YeSintered Metal, Chii ichocho?

ChiiSintered Sefa Kushanda Musimboti?

Muchidimbu kutaura, Nekuda kweiyo yakagadzikana porous furemu,sintered metal filtersndechimwe chezvinhu zviri nani zvekusefa

mazuvano.Zvakare, tembiricha yesimbi 'yakakwira, kudzvanywa, uye corrosion kuramba inogona kukubatsira

zadzisa zviri nyore basa rekusefa munzvimbo yakaoma, Kuparadzanisa uye kusefa kunze tsvina yakawandisa

haudi kana kukubatsira kuti ubvise magasi ehutsanana kana zvinwiwa zvepurojekiti yako.

Pamwe Iwe Haufanire kunzwa izwi iri zvakanyanya muhupenyu hwako hwezuva nezuva.

Asi mazuva ano, sintered simbi kuti ishandise zvakanyanya uye zvakanyanya mumaindasitiri akasiyana, iyo sintered simbi yakatanga kuita.

thetekinoroji yakakosha mune kumwe kugadzira.

ZvadaroChii Chaizvo chinonzi Sintered Metal?

Chaizvoizvo, ibazi repoda metallurgy indasitiri, muchidimbu, ndiyo 316L simbi isina tsvina.upfu kuburikidza neforoma

kuumba, tembiricha yepamusoro inonyura muchimiro uye basa remaitiro atinoda.

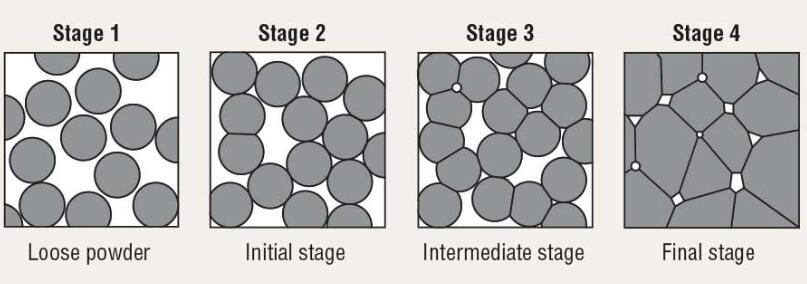

Zvadaro, Chekutanga, sinter.Chii chinonzi sintered?Sintering ndiyo nzira yekubatanidzauye kugadzira huremu hwakasimba hwezvinhu

nekupisa kana kudzvanywa pasina kuinyungudusa kusvika pakunyunguduka.Sintering chikamu chenzira yekugadzira inoshandiswa

nesimbi, ceramics,mapurasitiki, nezvimwe zvinhu.Wikipedia

Sezvinotsanangurwa neWikipedia, marudzi mazhinji ezvigadzirwa anogona kunyudzwa, uye akasiyana zvigadzirwa sintered zvigadzirwa

zvakasiyanaapplications.Ipapo pano tinodakutaura zvakawanda nezve sintered simbi.

NhoroondoyeSintering Metal

1. Ndiani Akagadzira sintering uye akatanga kushandisa zvigadzirwa zvakasvibiswa?

Zvinoenderana nezvinyorwa zvenhoroondo, iyo sintering process yakabuda panguva yechipiri yeindasitiri shanduko 18th century

muSwedenuye Denmark.Sintered iron yaivainowanikwa panguva yekunyungudutsa mumigodhi yemarasha.Asi kusvika 1980, vanhu

akatanga kushandisasintered simbi kumafuta ekusefa.Uye muna 1985, yekutanga yakashandisa HyPulse®filtration tekinoroji ye

kuenderera mberi slurry mafuta kusefa.

Inoratidza kutanga kwemasefa esimbi ane sintered.

Iyo setup yakaratidza kukodzera kwe sintered metal media yekupisa kusefa kwe slurry oiri ye carbon fiber.

nzira yekukura.

Sefa yakafamba nemazvo kwemakorekugadzira mafuta akachena ane zvinhu zvakaonda zvisingasviki 20 ppm solids uye yaive

pakupedzisira akavharapasi nekuda kwekuderera kwezvinhu zvinodiwa.Kubva ipapo, makambani ekuchenesa pasi rose avekuziva nezve

zvakanakira kusefa uchishandisasintered metal media ye catalyst faindi kubviswa mune slurry oiri mhinduro.

Kubva 1997, nzvimbo zhinji dzekunatsa muChina dzakaisa LSI yekuchenesa masisitimu ekubvisa zvinokurudzira mukugara.

fluid catalyticfracturing (RFCC) masisitimu.Gadzirisa Afiltration system ine (2) 24" LSI mafirita akaiswa muRFCC

system ine 1.4 miriyoninhamba masumbu (mt) gore rega rega kugona uye mhedzisiro yemafuta anotsvedza e180 mt / zuva.The

slurry mafuta ane zvakajairika 3,000 kusvika5,000 ppm solids inotarisa.Nguva yekutenderera inosiyana kubva pa2 kusvika ku8 maawa.The filtrate solids

zvinhu zviri pasi pe50 ppm.Sefa inodzorwanePLC yemunharaunda inotaurirana neinochenesa yakagoverwa

control system (DCS) yekugonesa mutyairi kutarisakucheneswa munzvimbo yekutonga.The systemane

yagara ichimhanya, ichipa bhizinesi renzvimbo ine yakachena filtrate kutikugadzira carbon black.Saka sezvo

application, iyo sintered Metal, Inonyanya kushandiswa kusefa kana kupatsanura solids kana magazinikubva mumvura kana

magasi nechinangwa chekuchenesa.

2. Saka Chii chinonzi Sintered Metal Sefa?

Tsanangudzo iri nyore ye sintered metal sefa:Isefa yesimbi inoshandisa simbi hupfu zvidimbu zvakafanana

particle sizekuumbwa nekutsikirira,high-temperature sintering process.Sintering ndiyo nzira ye

metallurgy uchishandisa hupfu-saizimiviri yesimbi dzakasiyana uye alloys mushure mekutsika.

Metallurgy inoitika nekupararira patembiricha iri pazasi penzvimbo yekunyungudika yehuni dzekupisa.

The simbi uye alloysinowanzoshandiswa nhasizvinosanganisira aluminium, mhangura, nickel, bhuronzi, simbi isina tsvina,

uye titanium.

Pane nzira dzakasiyana dzaungashandisa kugadzira hupfu.Zvinosanganisira kugaya, atomization,

uye kuora kwemakemikari.

3. Chii VaSintering Metal Filter Manufacturing Process

Zvadaro, saka pano, tinoda kutarisa maitiro ekugadzira Metal mafirita.kana uchida, tapota tarisa pazasi:

1.) Chii chinonzi Sintering, Sei Uchishandisa Sintering?

Tsanangudzo yakapusa sintering isimbi poda inosungirirwa pamwechete nekupisa kwakanyanya uye dzimwe nzira mukati

iyo module yaunoda.Mune iyo micron renji, hapana muganho wemuviri pakati pesimbi poda zvimedu,

ndosaka tichigona kudzora kureba kwepore

kuburikidza nekugadzira nzira.

Iyo porous cartridge ye sintering process inopa yakagadzikana chimiro chesimbi uye inopa

zvinhu nekushanda kwekusefa kwakasimba.

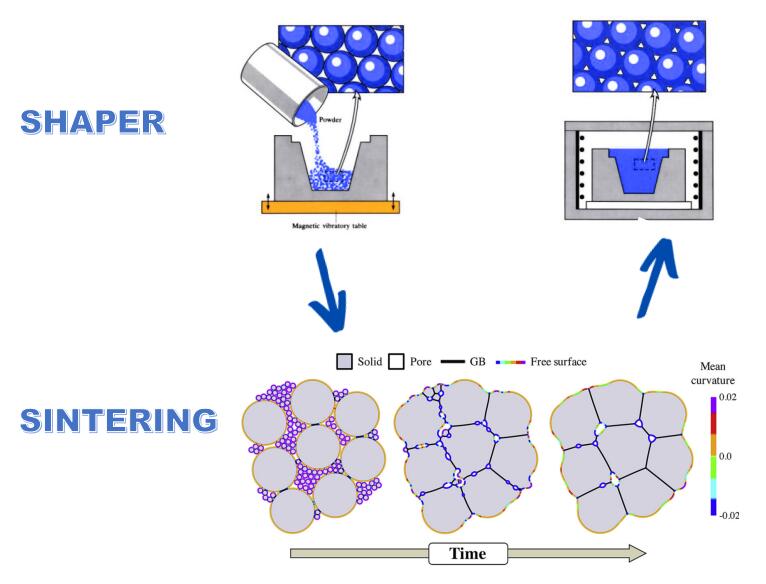

2.)3-MainMatanho eSintered Metal Filter Manufacturing

A: Nhanho yekutanga ndeyeKuwana iyo Power Metal.

Iyo simbi hupfu, Unogona kuwana simbi hupfu nekukuya, atomization, kana makemikari kuora.

Unogona kusanganisa simbi imwe chetehupfu neimwe simbi kuti igadzire alloy panguva yekugadzira,

kana kuti unogona kushandisa poda imwe chete.The advantage of sintering ndeyekutihaishanduri muviri

zvinhu zvesimbi zvinhu.Nzira yacho iri nyore zvokuti zvinhu zvesimbi hazvina kuchinjwa.

B: Kudhinda

Nhanho yechipiri ndeyekudurura hupfu hwesimbi muforoma yakagadzirwa kare iyo iwe unogona kugadzira sefa.

Iyo sefa musangano inoumbwa mukamuritembiricha uye pasi stamping.Kuwanda kwekumanikidzwa kwakaiswa

zvinoenderana nesimbi yauri kushandisa, sezvo simbi dzakasiyana dzine elasticity yakasiyana.

Mushure mekuita kwepamusoro-kudzvinyirira, simbi yehupfu inobatanidzwa mufodya kuti iite sefa yakasimba.Mushure me

high-pressure impact maitiro, unogonaisa sefa yesimbi yakagadzirwa muchoto chepamusoro-soro.

C: High-tembiricha Sintering

Mukuita sintering, zvimedu zvesimbi zvinosanganiswa kuti zvigadzire yuniti imwe chete isingasviki panonyungudika.

Iyi monolith yakasimba,yakasimba, uye ine porous sefa sesimbi.

Iwe unogona kudzora porosity yesefa nemaitiro zvichienderana nekuyerera kwemhepo kana mvura yekusefa.

Iyo sintered media giredhi zita rakaenzana nerevo kuyerera pore, kana avhareji saizi yepore yesefa.

Sintered metal media varizvinopihwa mumagiredhi 0.1, 0.2, 0.5, 1, 2, 5, 10, 20, 40 ne100. The filtration rating in

mvura yemagiredhi emedia 0.2 kusvika 20 iri pakati pe1.4 ne35 µmMhedziso.The filtration rating mugasi siyana

kubva 0.1 kusvika 100 µm zvachose.

4. Sei Kushandisa Metal Sintering Kuita Sefa?

Uyu mubvunzo wakanaka, sei kushandisa simbi kugadzira sefa?

Mhinduro yacho iri nyore, uye kunyange kune zvikonzero zvakawanda, mari yacho ndiyo inonyanya kukosha.

Why Cost ?

Hongu, sintered simbi ine chimiro chakatsiga uye inogona kushandiswazve, kuchena, uye kushandiswa kakawanda.

Uye zvakare, simbi dzakasiyana dzine yakagadzikana yemuviri nemakemikari zvimiro uye haina kukuvara nyore.

Ndokusaka akawanda uye akawanda Sintered Filters achishandiswa mumaindasitiri akasiyana.

5. Ndezvipi Zvisarudzo ZvezvinhuSintered Filters?

Nekuenderera mberi kwekuenderera mberi kweupfu metallurgy tekinoroji, kune dzimwe sarudzo dze

zvinhu zve sintered metal filters,

Iwe unogona kusarudza kubva kune mamwe akawanda simbi uye alloys kusangana akakosha zvinodiwa zvepamusoro

tembiricha uye kumanikidzwa, ngurakuramba etc, Main simbi zvinhu zvakadai se:

-

Stainless Simbi Sefa;316L, 304L, 310, 347 uye 430

-

Bronze

-

Inconel® 600, 625 uye 690

-

Nickel200 uye Monel® 400 (70 Ni-30 Cu)

-

Titanium

-

Alloys

Simbi yakawanda ichashandiswa mune ramangwana.

6. 8-Main Advantages eSintered Metal Filter

1. ) Corrosion resistance

Masimbi mazhinji anoshingirira mukuora, senge sulfides, hydrides, oxidation, nezvimwe.

2. ) Kuwedzera kunobatsira kubvisa tsvina

Kugadzirisa iyo porosity yekaturiji kune iyo fluid zvinoreva kuti iwe unogona kuwana yakakwana

kusefa yaunoda uye uwane amvura isina tsvina.Zvakare, sezvo sefa isingaparare,

kuita kwesefa hakukonzeri kuvepoyezvinosvibisa mumvura.

3. ) High Thermal Shock

Munguva yekugadzira, kupisa kwakanyanya kunogadzirwa, uye zvinhu zvemuviri zve

simbi idzi dzinobatsira kunwaSefa inotyisa zvikuru yekupisa.Nekuda kweizvozvo, unogona kushandisa izvi

mafirita mune zvakasiyana siyana zvekushandisa zvichienderana nekutithermal range yekushandiswa.

Great thermal shock zvakare inovimbisa inoshanda kusefa kwemvura pasina kunetsekana nazvo

kupisa kwekushandiswa.

4,) Inonzwisisika Kudzvinyirira Kudonha

Asintered simbi sefainogona kuchengetedza kudzvinyirirwa kwemvura mukushandisa kwako, nekudaro kuve nechokwadi

maximum operation.

Kudonhedza kushoma kushoma kunogona kukanganisa application yako.

5.) Tembiricha uye Pressure Resistance

Iwe unogona kushandisa iyi sefa mumashandisirwo ane tembiricha yakakwira uye kumanikidza pasina

kunetseka nezvesefa yako element.

Kushandisa sintered simbi mafirita mukugadzira maitiro emakemikari reactions uye gasi

mishonga yekurapa inovimbisa iwewana zvakanakisa kusefa mhedzisiro.

6. ) Yakaoma uye Inopikisa Kuputsa

Imwe bhenefiti yekushandisa sintered simbi sefa ndeyekuti yakasimba uye inoshingirira

kutyoka.

Munguva yekugadzira, kusungirirwa kwesimbi kunoitika pakudziya zvakanaka

pazasi pekunyungudika.

Chigadzirwa chinoguma isimbi yakaoma sintered sefa iyo inogona kumira zvakasiyana

nharaunda dzakaoma.

Semuenzaniso, unogona kuishandisa mumashandisirwo anoda kupokana pasina kutya kutyora.

7.) Fine Tolerances

Kushivirira kwakanaka kunoreva kuti yako sintered simbi sefa inogona kusefa mvura yako isina kuita.

Kana kusefa kwako kwapera, iyo sintered simbi sefa inochengeta zvimiro zvayo zvemuviri.

Nekudaro, zvingabatsira kana iwe uine chokwadi chekuti simbi yaunosarudza sefa yako haiite

ita nemumvura wauri kusefa

8.) Mhando yeGeometric Possibilities

Sintered cartridges inokubvumira kuti unakidzwe nemhando dzakasiyana-siyana dzejometri sarudzo.Unogona kubudirira

uku ndichipinza hupfumudhayi panguva yekugadzira.

Iyo mold ndiyo inofanirwa kugadzira sefa yako.

Naizvozvo, iwe wakasununguka kushandisa dhizaini zvinoenderana nezvaunoda.

Semuenzaniso, kana application yako ichida diki sefa, unogona kushandura dhizaini zviri nyore

kuwana diki

sintered simbi sefa.Saizvozvo, kana application yako iine dhizaini yakasarudzika, unogona nyore

shandura dhizaini mumold panguva yekugadzira.

7. Sintered Metal Filters Inoshanda Sei?

Dambudziko iri rinogonawo kunzi ndiyo inoshanda musimboti we sintered metal filters.Vanhu vazhinji vanofunga

kuti mubvunzo uyuzvakaoma zvikuru kupindura, uye hazvisi.Unogona kushamiswa neizvi, asi pamwe iwe

handizove mushure mekuverenga tsananguro yangu.

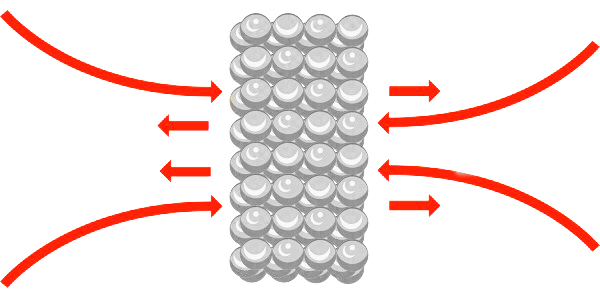

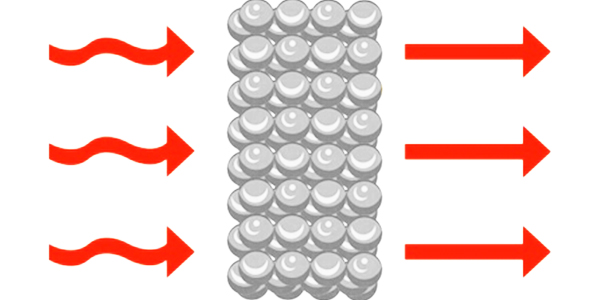

Sintered metal filters inobatsira zvikuru mafirita.Kuunganidzwa kwezvinosvibisa kunoitika pamusoro pe

the fluid;apo iyomvura inoyerera inopfuura nepasimbi sefa, iyozvidimbu zvakakura uye zvinosvibisa zvichave

yakasara kune rumwe rutivi rwekaturiji, asi kanakusarudza iyo inoshanda yekusefa nhanho yemvura yako, iwe

unofanirwa kuve nechokwadi kutiinogona kutosefa zvinodiwa.

Izvi Zvinodiwa Zvinosanganisira

1. Inosvibisa Kuchengetedza Backwash Kugona

2. Pressure Drop

Kuti dzvinyiriro idonhe, unofanira kufunga zvinhu zvakawanda.

Zvinhu izvi zvinosanganisira

AFluid viscosity, fluid velocity sezvainoyerera kuburikidza nesefa chinhu, uye hunhu hunosvibisa.

BHunhu hunosvibisa hunosanganisira chimiro chechidimbu, density, uye saizi.

Kana iyo yakasvibiswa yakaoma uye yakajairwa muchimiro, ichigadzira dense keke, ipapo kusefa kwepamusoro kwakakodzera.

Kubudirira kweSintered Metal Filtration kunoenderana

1.iyo yakawedzera dzvinyiriro inodonha kusvika painopinzwa mhedziso.

2.kugara kuyerera kwemvura.

Iwe unogona kuzadzisa mamiriro ekupedzisira nekukora zvinosvibisa izvo zvinowedzera kusvika painodonha mvura yekumanikidza.

Kumanikidza uku kunoramba kuchidonha kusvika kudonhedzwa kwepamusoro kweiyo viscosity yakapihwa uye kuyerera kwechiyero chinodiwa kwasvikwa.

Imwe nyaya yakakosha ndeyekugezwa kumashure kwesefa, iyo inoitwa nekudzvanya gasi kuchiratidziro uye nekukurumidza.

kuvhura vharafu yekuburitsa backwashsezvo musana unoitika.

A high reverse instantaneous pressure differential isgenerated.Inonyatsobvisa zvinosvibisa kubva kune sefa

element surface.The reversekuyerera kwemvura yakachena kuburikidza nesefa element inobvisa zvinosvibisa uye inoatungamira

kunze kwesefa.

Kuwedzera kwakadzikama mukudonha kwesimba kunoratidza kuenderana uye kwakafanana kugovera kwehukuru hwakasvibiswa.To

kuwana zvinoenderanakuita, iwe unofanirwa kuve nechokwadi kuti iyo sefa element yekudzvanywa inodonha yakagadzikana.Kana tembiricha

yekuchinja kwemvura, inobataviscosity yemvura.Muchiitiko ichi, kudzvinyirira kunodonha kudarika sefaelement will

kuwedzera uye kusazadzisa iyo filtration effect.

Naizvozvo, iwe unofanirwa kuchengetedza tembiricha yekushanda yesefa panguva yekusefa uye

sure thetembiricha yemvura uye kudzvanywa.Paunenge uchichenesa sefa, unofanirwa kutevera iyo

nzira yekugeza musana.

Iyo Sintered Metal Filters Inoshanda Sei?

Iwe unogona nyore kunzwisisa kana iwe uchitarisa zvinoteveraKushanda musimboti dhayagiramu

Sezvinotevera ndiyo huru8-Kindsyekushanda musimboti simbi filtration, tariro ichakubatsira iwe

kunzwisisa zvakawandakuti seiSintered simbi Sefa inogona kubatsiraye fiteration liquit, gasi uye inzwi.

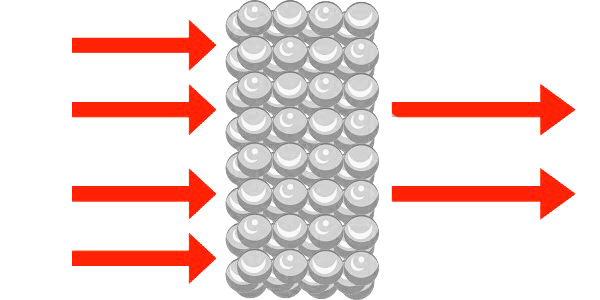

1.) Liquid & Gas Filtration/Separation

Sintered Metal mafirita anogona kuderedza kana kubvisa zvachose zvinhu kubva kune gasi kana mvura yepakati.

Chete chinhu chinogonainosanganisira asi haina kugumira kune yakamiswa zvidimbu (sediment, simbi machipisi, munyu, nezvimwewo),

algae, mabhakitiriya, fungi spores, uye zvisingadiwimakemikari/biological tsvina.Metal sefa pore saizi

inogona kuita kubva pa0.2 µm - 250 µm.

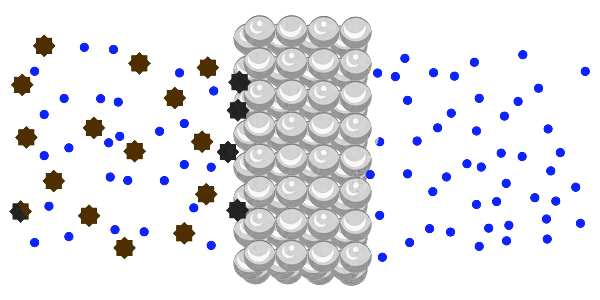

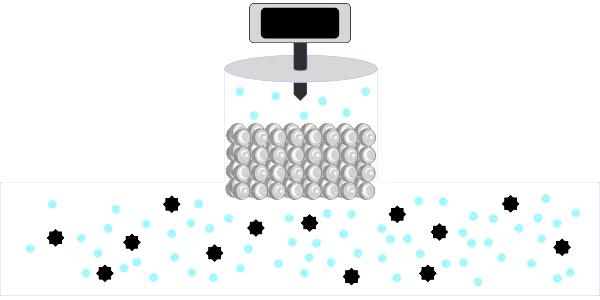

2.)Sparger

Zvimwe zveSparging Application:

Soda Carbonization

Beer Carbonization

OkisijeniKubviswa kweMafuta Anodyika

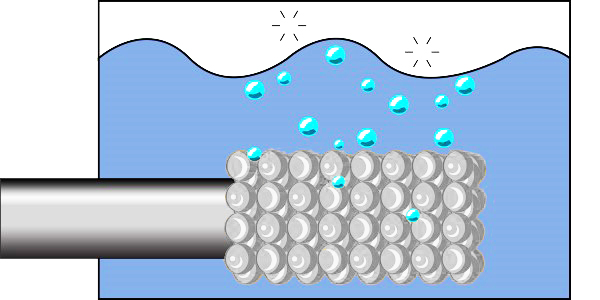

Sparging ndiko kuiswa kwegasi mumvura.Inoshandiswa kana kubvisa gasi risingadikanwi rakanyungudutswa

(kubvisa oxygen) kanamvura yakanyunguduka inoputika.Inogona zvakare kushandisa kuunza gasi mumvura (carbonization).

Traditional sparging yakagadzira mabubblesnehupamhi hwe 6 mm.PM sefa sparging inobvumira kunyange idiki

bubble dhayamita, nokudaro kuwedzera pamusoro penzvimbo yemabubbles achigadzira kuputika kwakanyanya

kushandiswa nekuderedza nguva yekuita.

3.) Breather Vents

Sintered simbi mafirita anoshandiswawo semhepo yekufema mumasilinda, magiya mabhokisi, manifolds, hydraulic system,

reservoirs, nezvimwezvirongwa.Mafemero ekufema anobvumira kuenzana kwekumanikidza uye mweya / gasi mukati nekubuda muhurongwa

uku ichivharira tunhu kubvakupinda muhurongwa.Masefa esimbi anogona kugezwa kumashure kuti abvise tumarara

nyaya, ichivapa hupenyu hurefu sekufemavent pane mamwe mafirita media.

4.) Sensor Protection

Sintered Metal Filters inogonawo kuchengetedza zvinhu zvemagetsi sevhavha, senge thermometers,

ma sensor akasiyana,keyzvikamu zvehurongwa hwekurapa, uye zvimwe zvigadzirwa zvinonzwisisika kubva mumvura,

zvinwiwa, tsvina, guruva, uyepressure fluctuation.

5.) Kudzora Kuyerera (Kudonhedza / Kudonha)

Iyo yakakosha sintered sefa inogona kudzora kuyerera mukati memhepo, gasi, vacuum, uye fluid kuyerera system.The

sefa yunifomupore saizibvumira kuenderana, kudzokororwa kuyerera kwemutemo uye kudzivirira mavharuvhu, sensors,

uye chimwe chinhu chiri pasi pemvuramuhurongwa kubvazvinosvibisa.Flow control inoshandiswa mune zvakadaro

kunyorera sepneumatic timers, gasi rekupa kutongazvinhu, uye kunonoka kwenguvazvinhu mu

mota applications.

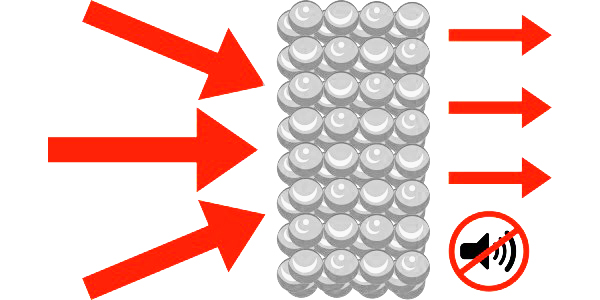

6.) Air Exhaust Silencers

Sintered mafirita anogona zvakare kusungirirwa kana sinter-yakasungirirwa kune chero inodiwa yekukodzera, ichivabvumira kushanda se

exhaust silencer.Iyo sefa haigone kuchengetedza solenoids uye manifolds kubva kune zvinosvibisa mukati me

system asi zvakare inoderedza ruzhamwero wekuneta kubva kune system.Masefa emhepo anobvisa silencer

wokuderedza mhepo inovhuvhuta kubva muhurongwa, iyoinoderedza kusvibiswa kubhururuka, Kudzivirira

zvakatipoteredza.

7.) Kuyerera / Kudzvinyirira Kuenzana

Sintered mafirita anogona kuenzana uye kudzora kuyerera kwehurongwa uye kudzvanywa.Kuenzana kunodzivirira

masisitimu anopesana nekuputikayemvura uye inogadzira kuyerera kwakafanana sezvo gasi kana mvura inofamba ichiyambuka

yunifomu pores.

8. Chii Chinonzi Sintered Filters Inoshandiswa?

Zvemubvunzo uyu, Chaizvoizvo vanhu vazhinji vanozobvunza Chii chinonzi sintered metal Filters?

Mushure mekuita kwakaoma kudaro, ko sintered metal filter cartridges ichashandiswa kupi?

Chokwadi ndechekuti iwe unogona kuwana aya mafirita mumaindasitiri akasiyana.

Zvishandiso zvakajairika zvinosanganisira zvinotevera.

1) Chemical processing

Iwe unogona kuwana sintered simbi mafirita mumakemikari solvent uye gasi kugadzirisa maindasitiri, kusanganisira iyo

indasitiri yenyukireya.Iyo ngura, tembiricha yakakwira, uye isingaite kumakemikari inoita sintered simbi

kusefa mukana wakasiyana mukati

indasitiri yekugadzira makemikari.

2) Petroleum refining

Kukwenenzvera petroleum, kunyatsosefa mafuta akasiyana

Isu tinofanirwa kushandisa akasiyana mafirita esimbi zvinoenderana nedhigirii level kuti tipedze kusefa kweiyo

mafuta chaiwo kubvaiyo feed stock.Ehe, sintered simbi mafirita anogona kukubatsira iwe kuzadzisa ichi chinangwa.

Nekuti mafirita esimbi haaite zvemakemikari nemafuta.

Naizvozvo, iyo chaiyo mafuta ichave isina chero inosvibisa mushure mekusefa.

Mukuwedzera, iwe unogona kuishandisa pakupisa kusvika ku700 °, iyo inowanikwa mukunatsa petroleum.

3.) Kugadzira simba

Kugadzirwa kwemagetsi emagetsi kunoda kuenderera mberi kwekushanda kweturbine.Zvakadaro, the

environment muiyo turbineinoshanda kazhinji inoda kusefa kuti iwane muviri wemvura mukati

iyo turbine isina chero tsvina.

Kana turbine yakazadzwa netsvina, inosimuka uye kudzivirira turbine kutenderera,

uye ipapo turbine ichadarokwete kugadzira magetsi.Iwe unogona kushandisa sintered simbi mafirita kuve nechokwadi

kugadzirwa kwemagetsi kunoshanda uye kwakanaka.

Masefa aya anoshandiswa kugadzira magetsi nekusefa mvura kubva muturbine.

Nemhaka yokuti haisi kuparadzwa nemvura, turbine ichashanda kwenguva yakareba.

4.) Kugadzirwa kwegasi

Imwe nzvimbo yakakosha yekushandisa kune sintered simbi mafirita kugadzirwa kwegasi.

Sintered simbi mafirita anobatsira kwazvo mukugadzira gasi nekuti haaite negasi,

uye unogona kuzvishandisamunzvimbo dzakasiyana.

5.) Chikafu uye chinwiwa

Metal mafirita anobvisa zvakakosha zvinovaka muviri uye majusi muindasitiri yezvekudya uye zvinwiwa.

Metal mafirita anonyatso kusefa uye kudzivirira izvi zvinovaka muviri kuti zvisakukurwe panguva yekugadziriswa.

Kubatsira kwemasefa esimbi mamwechete ndeyekuti haaite nekudya chaiko kana zvinwiwa.

Paunenge uchishandisa aya mafirita anovimbisa kunaka kwemaitiro ako ekugadzira.

9. ChirudziiSintered Metal FiltersHENGKO Can Supply ?

HENGKO main supply 316L, 316 uye bronze sintered simbi mafaira.chimiro chikuru senge runyorwa runotevera:

1.Stainless Simbi SefaDisc,

2.StainlessSimbi SefaTube,

3.Stainless Simbi SefaPlate,

4.Stainless Simbi SefaCups,

nezvimwewo, chero chimiro chinoda purojekiti yako.

Chokwadi, tinopaOEM Service

1.OEMShape:Disc, Mukombe,Tube, Plate ect

2.CustomizeSize, Kureba, Kufara, OD, ID

3.Customized Pore Size /Apertureskubva 0.1μm - 120μm

4.Gadzirisa Hukobvu hwakasiyana

5.Mono-layer, Multi-layer, Mixed Materials

6.Yakabatanidzwa dhizaini ine 304 Stainless simbi dzimba

Kuti uwane Yako Zvimwe OEM ruzivo, ndapota taura HENGKO Nhasi!

Uchiri Nemibvunzo Yese seKuziva Ruzhinji Ruzhinji rweiyo Humidity Monitoring Sensor,

Ndapota inzwa Wakasununguka Kutibata Nesu Iye zvino.

Uyewo UnogonaTitumirei EmailZvakananga Sezvinotevera:ka@hengko.com

Tichatumira Kudzoka Nemaawa makumi maviri nemana, Tinotenda neMurwere Wako!

Tumira meseji yako kwatiri:

Nguva yekutumira: Aug-20-2022