-

High-Capacity Stainless Steel Inline Gasi Sefa yeKugadzirwa Kwemishonga

Tsanangudzo Maitiro Gasi Specialty Sefa, inozivikanwawo sePoint-to-Use Inline Filter, yakanyatsogadzirirwa kuti semiconductor indasitiri inyatso rem...

View Detail -

Innovative High Purity, High Pressure Gasi Diffuser Solutions Yakagadzirirwa Semiconductor...

Tsanangudzo Iyo Diffuser Sefa ndeye yekucheka-kumucheto mhinduro yakagadzirirwa kukurumidza kufema maapplication mumakamuri ekutsvaira anoshandiswa mune semiconductor murume ...

View Detail -

Yepamusoro-Kuita IGS Surface Mount C Seal Mafirita eSemiconductor Gasi Delivery Systems.

Tsanangudzo HENGKO Surface Mount Mafirita akagadzirwa kuti asangane nezvinodiwa zveyakasanganiswa gasi masisitimu anoshandiswa mune semiconductor OEM zvishandiso. Kupa ...

View Detail -

Porous Metal Inline Point-ye-Kushandisa Sefa yeCompressed Gas Application

Tsanangudzo Maitiro Gasi Specialty Sefa, inozivikanwawo sePoint-to-Use Inline Filter, yakanyatsogadzirirwa kuti semiconductor indasitiri inyatso rem...

View Detail -

Yakakwira Kudzvanya Gasi Diffusers Yakagadzirirwa iyo Semiconductor Indasitiri: Precision Filtration ...

Tsanangudzo Iyo Diffuser Sefa ndeye yekucheka-kumucheto mhinduro yakagadzirirwa kukurumidza kufema maapplication mumakamuri ekutsvaira anoshandiswa mune semiconductor murume ...

View Detail -

Tsika IGS Surface Mount C Seal Mafirita eAdvanced Gasi Delivery Systems muSemiconduc...

Tsanangudzo HENGKO Surface Mount Mafirita akagadzirwa kuti asangane nezvinodiwa zveyakasanganiswa gasi masisitimu anoshandiswa mune semiconductor OEM zvishandiso. Kupa ...

View Detail -

Stainless Steel Inline Porous Sefa yeCompressed Air uye Gasi Systems

Tsanangudzo Maitiro Gasi Specialty Sefa, inozivikanwawo sePoint-to-Use Inline Filter, yakanyatsogadzirirwa kuti semiconductor indasitiri inyatso rem...

View Detail -

Yakakwira Kudzvanya Yakakwirira Chenesa Gasi Sefa yeSemiconductor Indasitiri HF akatevedzana naHENGKO

Tsanangudzo Iyo yakakwira-kudzvanywa gasi sefa yakanyatso kugadzirirwa kushandiswa mukudzvanya, yakakwira-kuchena gasi kuburitsa masisitimu uye ekupedzisira-yepamusoro-kuchena gasi makabati ...

View Detail -

HENGKO® High Purity Semiconductor Gasi Sefa

High kuchena akatevedzana mafirita akagadzirirwa kusefa semiconductor magasi. Iyi gungano yakashongedzwa zvizere inoburitsa 0.003 micron particle yakabatsira kuchengetedza. Semi...

View Detail -

Sintered In-line Metal Gasi Sefa yeSemiconductor Gasi Kuchenesa System

Sintered in-line simbi gasi mafirita anoshanda kudzinga kusvibiswa kunosanganisira mwando, okisijeni, kabhoni dhaikisaidhi, kabhoni monoxide, mahydrocarbon uye simbi kabhoni ne ...

View Detail -

HENGKO High Purity Porous Metal Chamber Diffusers Dombo rekuchena gasi kusefa ...

HENGKO Porous Metal Diffusers inokurumidza kuburitsa vacuum makamuri kumhepo iyo inoderedza kutenderera nguva uye inowedzera kubuda. Simbi yedu isina tsvina diffu...

View Detail -

Tembiricha uye Humidity Sensor yeSemiconductor Yakachena Kamuri Temperature Humidity Contr...

Chigadzirwa Ratidza Tembiricha uye hunyoro hwenzvimbo yakachena zvinonyanya kutsanangurwa zvinoenderana nezvinodiwa nemaitiro, asi pasi pemamiriro ekusangana ...

View Detail -

Sintered SS 316L Stainless simbi murazvo-uchapupu inodzivirira probe sefa dzimba maindasitiri ...

Kuputika-proof sensor maassemblies anogadzirwa ne316 Stainless simbi yekunyanya kudzivirira ngura. Sinter-bonded flame arrestor inopa gasi kupararira ...

View Detail -

316L murazvo-uchapupu sefa dzimba co2 semiconductor microns modbus sensor filter probe ho ...

HENGKO explosion-proof sensor housing inogadzirwa ne316L simbi isina tsvina uye aruminiyamu yekudzivirira kukuru kwekuora. Sinter-bonded flame arrestor inopa ...

View Detail

Semiconductor Gasi Sefa:

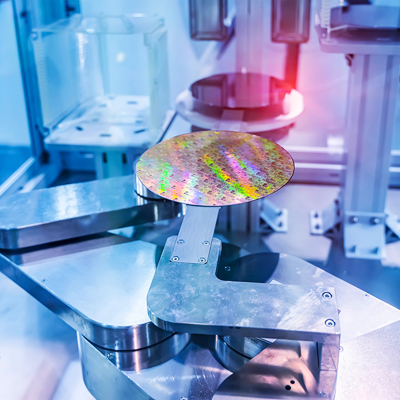

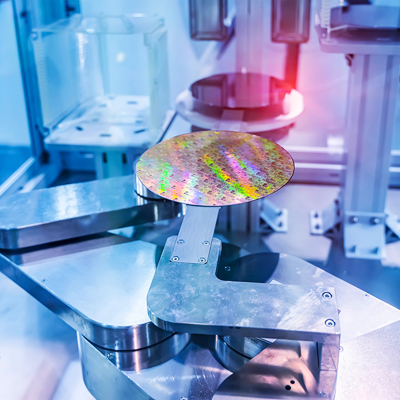

Kuve nechokwadi Isingagoneki Gasi Kuchena muChipmaking

Munyika yakaoma yekugadzira semiconductor, uko kurongeka uye kuchena kwakakosha, kunaka kwe

magasi anoshandiswa anoita basa rakakosha pakuona kubudirira kwechirongwa. Kusachena, kunyangwe pamazinga asina magumo,

inogona kukanganisa kutenderera kwakapfava kwemicrochips, zvichiita kuti ive isina kukwana uye isingashandisike. Kuchengetedza

iyi yakaoma maitiro, semiconductor gasi mafirita anomira sevachengeti vasingatenderi, vachibvisa zvine hungwaru zvinosvibisa.

uye kuve nechokwadi chepristine mhando yemagasi anoyerera nemumitsetse yekugadzira.

Kune akawanda akanakisa maficha uye mabhenefiti e sintered simbi mafirita

1. Yakagadzirwa muState-of-the-Art Cleanroom Nzvimbo

Aya mafirita anozvarirwa mukamuri-ye-the-art yekuchenesa, nharaunda umo mamiriro asina kuchena anochengetedzwa zvine hungwaru kuderedza chero kusvibiswa kungangoitika. Vanoita gadziriro yakaomarara yekugadzira, kutanga nekurukisa simbi pasi pemhepo yakanatswa. Iyo inotevera deionized water flush, inoteverwa ne-high-pressure, yakasefa nitrogen purge, inobvisa chero zvimedu zvinononoka uye inoderedza njodzi yekudeuka kwechidimbu.

2. Exceptional Particle Removal Efficiency

Iine kushamisa kunoshamisa kusefa kwe9 LRV ye0.003μm zvimedu, inonamatira kune yakaomesesa zviyero zvakatemerwa neSEMI F38 uye ISO 12500 nzira dzekuyedza, aya mafirita anobvisa zvinobudirira chero zvimedu zvinogadzirwa nekuora uye zvimedu zvinogadzirwa kubva muzvikamu zvinofamba, kuve nechokwadi kuchena kwakachena kweiyo. magasi.

3. Superior Mechanical Simba

Yakayedzwa zvine simba kuti ivimbise kusimba kwakasarudzika mukudiwa kwekugadzira maitiro uye nharaunda dzinowanzo shandisa yakakwira gasi kudzvanywa, mafirita aya anopa kushanda kusingazungunuke mukati mehupenyu hwavo hwose.

4. Kupfuura Yepamusoro Indasitiri Maitiro

Kupfuura iyo yakaomesesa gasi inobata kusefa zvinodiwa pakugadzirisa semiconductor, mafirita aya anoedzwa zvakasimba kuti ave nechokwadi chekuti anosangana nekukosha kwekusefa, kunyatso kudzora kuyerera, uye mwero wekuchengetedza unodiwa nemasisitimu ekutakura gasi mukugadzira semiconductor.

5. Kuzvipira Kusingazununguki kune Chengetedzo

Kuchengetedza kubva pakuratidzwa kune zvinopisa, zvinoparadza, zvine muchetura, uye pyrophoric maitiro magasi, mafirita edzimba anoongororwa nekunakigwa kwekuvuza, kuve nechokwadi kuti vawana kuburitsa kunoshamisa kuri pasi pe1x10-9 atm scc/sekondi. Uku kuzvipira kusingazungunuke kune kuchengetedzwa kunovimbisa kuti magasi ane njodzi arimo uye anodzivirirwa kubva mukukuvadza.

6. Kusagadzikana Kuchena kweChipmaking Excellence

Kuburikidza nehunyanzvi hwavo hwekusefa, kuzvipira kusingazungunuke kune chengetedzo, uye kutevedzera zviyero zvepamusoro zveindasitiri, mafirita egasi aya anoita basa rakakosha kuchengetedza maitiro akaomarara ekugadzira semiconductor. Ivo vanomira sevachengeti vekuchena, vachiona kuti chete magasi akachena anoyerera nemumitsetse yekugadzira, achigadzira nzira yekusikwa kwepamusoro-inoshanda microchips inosimbisa nyika yedu yemazuva ano.

Mhando dzeSemiconductor Filters

Semiconductor mafirita anoshandiswa mumhando dzakasiyana dzekushandisa, kusanganisira:

* Kugadzirwa kwemagetsi:

Semiconductor mafirita anoshandiswa kubvisa zvimedu kubva kune Ultrapure mvura, magasi, uye makemikari anoshandiswa mukugadzira semiconductors.

* Kemikari mechanicha planarization (CMP):

Semiconductor mafirita anoshandiswa kubvisa zvimedu kubva kuCMP slurries, ayo anoshandiswa kupurisa semiconductor wafers.

* Biomedical:

Semiconductor mafirita anoshandiswa kubvisa zvimedu kubva mumvura inoshandiswa mukuongororwa kwekurapa uye kurapwa.

* Environmental:

Semiconductor mafirita anoshandiswa kubvisa zvimedu kubva mumhepo nemvura.

Kune marudzi mana makuru e semiconductor mafirita:

1. Masefa eMembrane:

Masefa eMembrane anogadzirwa nefirimu rakatetepa, rine porous iro rinotendera kuti zvinwiwa zvipfuure nekuteya zvimedu.

2. Masefa akadzama:

Masefa akadzama anogadzirwa nemubhedha wakakora, une tortuous wezvinhu zvinoteya zvimedu pazvinoyerera nepasefa.

3. Adsorbent mafirita:

Adsorbent mafirita anogadzirwa nechinhu chinokwezva uye chinobatirira pane zvimedu.

4. Sintered metal filters

Sintered metal filters imhando yekudzika sefa iyo inowanzoshandiswa mukugadzira semiconductor. Iwo anogadzirwa nekunyudza simbi yakatsetseka poda kuita porous chimiro. Sintered simbi mafirita anozivikanwa nekusimba kwazvo, yakanyanya kusefa kunyatsoita, uye kugona kutsungirira tembiricha yakakwira uye kumanikidza.

Zvakanakira sintered simbi mafirita ekugadzira semiconductor:

* High durability:

* Yakakwira kusefa kunyatsoshanda:

* Hupenyu hurefu:

* Chemical kuenderana:

Zvishandiso zvesintered simbi mafirita mukugadzira semiconductor:

* Kucheneswa kwegasi:

Sintered simbi mafirita chikamu chakakosha cheiyo semiconductor kugadzira maitiro, zvichibatsira kuve nechokwadi kugadzirwa kwemhando yepamusoro semiconductor zvishandiso.

Mhando ye semiconductor sefa inoshandiswa mune imwe application zvinoenderana nehukuru hwezvimedu zviri kubviswa, rudzi rwemvura iri kusefa, uye chiyero chinodiwa chekusefa.

Heino tafura inopfupikisa mhando dzakasiyana dze semiconductor mafirita:

| Rudzi rwesefa | Tsanangudzo | Applications | Image |

|---|---|---|---|

| Sefa dzeMembrane | Yakagadzirwa nefirimu rakatetepa, rine porous rinobvumira zvinwiwa kupfuura apo ichiteya zvimedu. | Kugadzirwa kwemagetsi, CMP, biomedical, zvakatipoteredza | |

| Sefa dzakadzama | Yakagadzirwa nemubhedha mukobvu, wakatsemuka wezvinhu zvinoteya zvimedu pazvinoyerera nepasefa. | CMP, biomedical, zvakatipoteredza | |

| Adsorbent filters | Yakagadzirwa nechinhu chinokwezva uye chinobatirira pane zvimedu. | Kugadzirwa kwemagetsi, CMP, biomedical, zvakatipoteredza | |

| Sintered metal filters | Yakagadzirwa nekuputira simbi yakatsetseka muhupfu. | Kucheneswa kwegasi, kusefa kwemakemikari, kusefa kwemvura kwekupedzisira, CMP slurry filtration. | Sintered metal filters ye semiconductor |

Application

Sintered simbi semiconductor gasi mafirita anoshandiswa zvakanyanya mumhando dzakasiyana dzekushandisa muindasitiri yesemiconductor. Zvimiro zvavo zvakasarudzika, senge yakakwira kusefa kushanda zvakanaka, kusimba, uye kugona kutsungirira tembiricha yakakwira uye kumanikidzwa, inovaita chinhu chakakosha chegasi rekutakura masisitimu mukugadzira semiconductor.

Heano mamwe emamwe mashandisirwo eiyo sintered simbi semiconductor gasi mafirita:

1. Kugadzirwa kwewafer:

Sintered metal mafirita anoshandiswa kuchenesa magasi anoshandiswa mukugadzira wafer, senge nitrogen, hydrogen, uye oxygen. Aya magasi akakosha pakuita senge epitaxial kukura, etching, uye doping.

2. Kemikari kusefa:

Sintered simbi mafirita anoshandiswa kusefa makemikari anoshandiswa mukugadzira semiconductor, senge acids, mabhesi, uye zvinonyungudutsa. Makemikari aya anoshandiswa kune zvakasiyana-siyana, kusanganisira kuchenesa, etching, uye polishing.

3. Ultrapure sefa yemvura:

Sintered simbi mafirita anoshandiswa kusefa ultrapure mvura (UPW) inoshandiswa mukugadzira semiconductor. UPW yakakosha pakuchenesa nekusuka mawafers, pamwe nekugadzira makemikari.

4. CMP slurry filtration:

Sintered simbi mafirita anoshandiswa kusefa CMP slurries, ayo anoshandiswa kupukuta semiconductor wafers. CMP inzira yakakosha mukugadzira microchips.

5. Kupepeta-kwekushandisa (POU):

Sintered simbi mafirita anowanzo shandiswa sePOU mafirita, ayo anoiswa zvakananga panzvimbo yekushandisa kuti ape iyo yepamusoro yepamusoro yekusefa. Mafirita ePOU anonyanya kukosha kune maapplication uko kuchena kwegasi kwakakosha, senge mukugadzirwa kwemamicroprocessors uye mamwe madhizaini epamusoro.

6. High-purity gasi kubata:

Sintered simbi mafirita anoshandiswa mune yakakwira-kuchena gasi kubata masisitimu kubvisa zvinosvibisa kubva kumagasi anoshandiswa mukugadzira semiconductor. Izvi zvinosvibisa zvinogona kusanganisira zvimedu, unyoro, uye organic komisheni.

7. Microelectronics kugadzira:

Sintered simbi mafirita anoshandiswa mukugadzira mamicroelectronics, senge makomputa, mahwendefa, nharembozha, maIoT sensors, uye midziyo yekudzora.

8. Micro-electromechanical systems (MEMS) kusefa:

Sintered metal mafirita anoshandiswa muMEMS kusefa, inova maitiro ekubvisa zvinosvibisa kubva kune micro-electromechanical systems. MEMS inoshandiswa mumhando dzakasiyana dzekushandisa, kusanganisira masensa, actuators, uye transducer.

9. Kusefa mudziyo wekuchengetedza data:

Sintered simbi mafirita anoshandiswa mukusefa mudziyo wekuchengetera data, inova maitiro ekubvisa zvinosvibisa kubva kumidziyo yekuchengetedza data, senge hard drive uye solid-state dhiraivha.

Pamusoro peaya mashandisirwo chaiwo, sintered simbi semiconductor gasi mafirita anoshandiswawo mune akasiyana mamwe maapplication muindasitiri yesemiconductor. Kuita kwavo kwakasiyana-siyana uye kuvimbika kunovaita chishandiso chakakosha kune vanogadzira semiconductor.

Kutsvaga yepamusoro-mhando sintered simbi semiconductor gasi mafirita?

HENGKO ndiyo yako yekuenda-kufambidzana yeOEM mhinduro mune semiconductor yekugadzira masisitimu.

Yedu chaiyo-engineered mafirita anovimbisa kuvimbika uye kugona mumaitiro ako, achikupa iwe mupendero mumusika wemakwikwi.

Sei Kusarudza HENGKO's Mafirita?

* Hunhu hwepamusoro uye kusimba

* Yakagadzirirwa mhinduro kuti ikwane zvaunoda chaizvo

* Kuwedzera kuita kwekugadzira semiconductor

Usarege matambudziko ekusefa achidzora kugadzirwa kwako.

Svika kwatiri nhasi kuti tiongorore kuti mafirita edu esintered simbi anogona sei kushandura hurongwa hwako hwekugadzira.

Tibate paka@hengko.com

Batira pamwe neHENGKO uye tora nhanho kuenda kune kugona mukugadzira semiconductor!