-

Customized sintered porous Stainless simbi waya mesh simbi humburumbira sefa

Sintered Metal Mesh iwaya yekusefa jira rakagadzirwa nekutsikirira akawanda-layer Stainless simbi yakarukwa jira rewaya, rozoiswa pamwechete muchoto chevacuum. Izvi...

View Detail -

Sintered 304 316l Stainless simbi multilayer waya mesh micron filter screen disc

Chigadzirwa Tsanangudzo Sintered waya mesh ndeye yakawanda-yakapetwa yewaya mesh / simbi sefa jira rakanyudzwa sendiro yese nemaitiro ekunyudza kana kupararira...

View Detail -

Yakadzvanywa mhepo isina simbi isina waya mesh sefa katuriji ye sterile process mweya uye g...

Sintering inzira inosanganisira kushandiswa kwekupisa uye kudzvanywa kwekubatanidza nzvimbo dzekusangana dzewaya dzese pamwechete kuti dzigadzire waya wakachengetedzwa wakachengetedzwa mesh ...

View Detail -

Sintered Stainless simbi waya mesh sefa chubhu (sefa humburumbira) inoshandiswa mupetroleum, che...

Sinter wire mesh mafirita anowanzo shandiswa kucheneswa uye kusefa kwemvura uye gasi, kupatsanurwa uye kudzoreredzwa kwezvimedu zvakasimba, transpiration coolin...

View Detail -

1.0-100um sintered porous simbi yesimbi katuriji sefa mesh inoita mumvura...

Sinter wire mesh mafirita anowanzo shandiswa kucheneswa uye kusefa kwemvura uye gasi, kupatsanurwa uye kudzoreredzwa kwezvimedu zvakasimba, transpiration coolin...

View Detail -

Stainless simbi mesh sefa pneumatic exhaust muffler, hex. kiyi pazamhu

Muffler Silencer Model G M5 1/8'' 1/4'' 3/8'' ...

View Detail -

HBSL-SSDM Chirume Breather Vent Flat Sintered Mesh Pneumatic Air Silencer Mufflers Solenoi...

Pneumatic Sintered Mufflers Mafirita anoshandisa porous sintered bronze filter element yakachengetedzwa kune yakajairwa pombi fittings. Aya compact uye asingadhure mufflers ...

View Detail

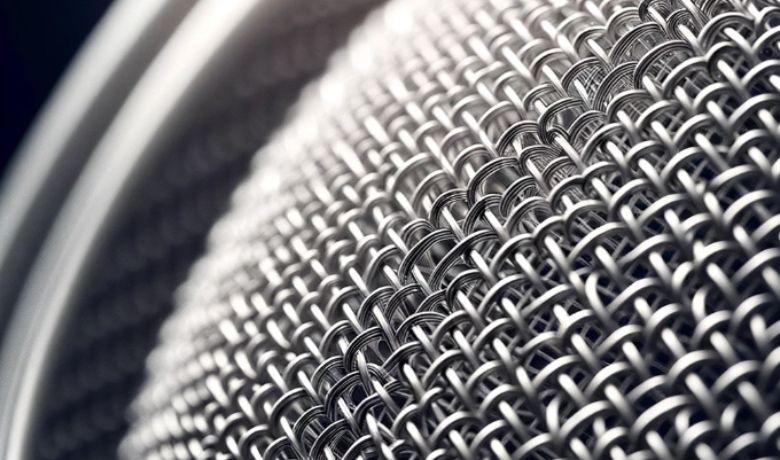

Chii chinonzi sintered mesh?

Zviri nyore kutaura, A sintered mesh isimbi sefa inogadzirwa nekusanganisa pamwe akawanda akarukwa waya mesh.

kuburikidza nenzira inonzi sintering.

Munguva yekupisa, mesh layers inopisa uye inomanikidzwa pamwe chete, ichigadzira yakasimba uye yakagadzikana chimiro.

Chigadzirwa chinoguma chine yunifomu pore saizi uye inopa yakanakisa kusefa kugona, ichiita kuti ive yakakodzera

akasiyana maapplication mumaindasitiri uko kwakaringana uye kwakavimbika kusefa kunodiwa.

Sei Uchishandisa Sintered Stainless Steel Mesh?

Sintered Stainless simbi mesh inopa akati wandei mabhenefiti ayo anoita kuti ive sarudzo yakanaka kune akasiyana maindasitiri ekushandisa:

1.Durability:

Sintered Stainless Simbi inoshingirira mukuora, ichiita kuti ive yakakodzera kunharaunda dzakaoma uye kushandiswa kwakawedzerwa.

2.High Filtration Efficiency:

Iyo sintering process inogadzira yunifomu pore chimiro chinobvumira kukwenenzverwa kwezvimedu, zvichipa yakanyanya kusefa kunyatsoita zvese zvinwiwa uye magasi.

3.Customizable Pore Sizes:

Vagadziri vanogona kugadzira masintered meshes ane akasiyana pore saizi kuti asangane nezvinodiwa zvekusefa, zvichiita kuti aite zvakasiyana-siyana kune akasiyana maapplication.

4.Mechanical Simba:

Sintered Stainless simbi mesh yakasimba uye inokwanisa kumirisana nekumanikidza kwakanyanya, tembiricha, uye kuyerera kwemazinga pasina kukanganisa.

5.Easy Kuchenesa:

Aya meshes anogona kucheneswa uchishandisa nzira dzakasiyana (semuenzaniso, backflushing, ultrasonic kuchenesa), izvo zvinowedzera hupenyu hwavo uye kuchengetedza kushanda.

6.Chemical Resistance:

Vanokwanisa kubata zvakasiyana-siyana zvemakemikari, zvichiita kuti zvive zvakakodzera kushandiswa mukugadzirwa kwemakemikari, zvokudya uye zvinwiwa, uye maindasitiri emishonga.

7.Non-chepfu uye Yakachengeteka:

Kuve yakagadzirwa nesimbi isina tsvina, haina chepfu uye haibvisi zvinhu zvinokuvadza muzvinhu zvakagadziriswa.

8.Mutengo-Kubudirira:

Nepo mari yekutanga ingave yakakwira, kusimba uye kushandiswazve kwe sintered Stainless simbi mesh kunogona kutungamirira kukuchengetedza mutengo kwenguva refu.

9.Applications muDiverse Industries:

Iwo anoshandiswa munzvimbo dzakasiyana siyana, kusanganisira kurapwa kwemvura, mafuta uye gasi, mishonga yemishonga, uye kugadzira chikafu, nekuda kwekusiyana-siyana uye kuvimbika.

Aya maitiro anoita sintered Stainless simbi mesh sarudzo yakanaka kune maindasitiri anoda yakakwirira-performance filtration solution.

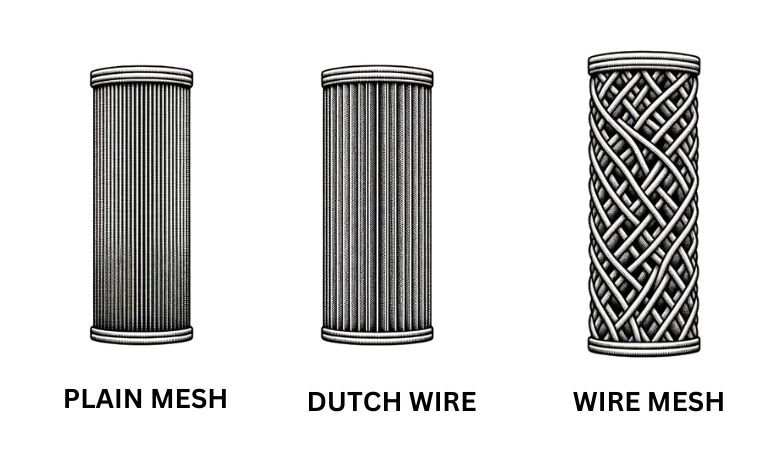

Mhando dzeSintered Mesh Sefa ?

Sintered mesh mafirita anouya mumhando dzakasiyana zvichienderana nechimiro chavo, maseru, uye chaiwo mashandisirwo. Mamwe emhando dzakajairika anosanganisira:

1. Single Layer Sintered Mesh:

Yakagadzirwa kubva pachikamu chimwe chete chewaya mesh yakarukwa yakasiiwa kuti iwedzere kusimba kwayo uye kusimba.

2. Multi-layer Sintered Mesh:

Izvi zvinosanganisira kurongedza matinji ewaya mesh yakarukwa wobva waabatanidza pamwechete. Iyo yakawanda-layer chimiro inosimudzira simba remakanika uye kurongeka kwesefa.

3. Sintered Square Woven Mesh:

Yakagadzirwa kubva masikweya akarukwa waya mesh akaturikidzana, iyi mhando inopa yunifomu pore saizi uye inowanzoshandiswa mumhando dzakasiyana dzekusefa.

4. Dutch Woven Sintered Mesh:

Izvi zvinosanganisa akawanda akaturikidzana eDutch akarukwa waya meshes, ayo anobva apiswa. Mhedzisiro yacho isefa ine hunyanzvi hwekusefa.

5. Perforated Metal Sintered Mesh:

Rudzi urwu runobatanidza chidimbu chimwe chete kana kupfuura chewaya yakarukwa nerukwa rwesimbi ine perforated. Iyo perforated simbi inopa simba rakawedzerwa, nepo waya mesh maseru achipa kusefa.

6. Sintered Fiber Felt Mesh:

Panzvimbo pewaya yakarukwa, sefa iyi inoshandisa meti yetambo dzesimbi. Mafiibhi anosanganiswa pamwe chete kugadzira porous svikiro iyo yakanakisa kune yakakwirira-tembiricha uye yakakwirira-viscosity application.

7. Sintered Metal Powder Mesh:

Mhando iyi inogadzirwa nekunyungudutsa simbi hupfu kuita porous filtration medium. Inowanzo shandiswa kana kukwenenzverwa kwakanaka uye yakakwirira tsvina inobata masimba inodiwa.

Imwe neimwe yemhando idzi ine zvayakanakira uye yakagadzirirwa kune chaiwo maapplication. Pakusarudza sintered mesh sefa, zvakakosha kuti utarise chimiro chechinhu chiri kusefa, saizi yaidiwa pore, mamiriro ekushanda, uye zvimwe zvinhu zvine chekuita.

Maitiro ekusarudza Kurudyi Sintered Mesh Mafirita kune Yako yekusefa mudziyo?

Kusarudza iyo chaiyo sintered mesh sefa kune yako yekusefa mudziyo kwakakosha pakuita kwakaringana. Heino nhanho-ne-nhanho gwara rekukubatsira kuita sarudzo ine ruzivo:

1. Sarudza Zvido zvekusefa:

* Chikamu Saizi: Nzwisisa diki diki saizi yaunoda kusefa kunze. Izvi zvinokutungamira kuti usarudze saizi chaiyo yepore ye sintered mesh.

* Flow Rate: Funga nezve yaunoda kuyerera mwero kuburikidza nesefa. Mamwe ma mesh marudzi anobvumira kukurumidza kuyerera mitengo pasina kukanganisa kusefa kushanda zvakanaka.

2. Ongorora Operating Conditions:

Tembiricha: Ita shuwa kuti yakasarudzwa sintered mesh inogona kumira tembiricha yekushanda kwemaitiro ako.

Kudzvinyirira: Mamwe maitiro ekusefa anosanganisira kumanikidzwa kwakanyanya. Sarudza mesh inogona kubata aya madhiri pasina kukanganisa.

Kemikari Inopindirana: Ita shuwa kuti zvinhu zve mesh zvinoenderana nezvinhu zviri kusefa, kunyanya kana makemikari kana zvinoparadza zvinhu zvakabatanidzwa.

3. Kusarudzwa kwezvinhu:

Simbi isina simbi ndiyo inonyanya kushandiswa kune sintered mesh nekuda kwekusimba kwayo uye kuramba corrosion. Nekudaro, zvimwe zvinhu zvakaita setitanium kana Monel zvinogona kunge zvakanyanyokodzera kune chaiwo maapplication.

4. Sarudza Rudzi rweSintered Mesh:

Single Layer vs. Multi-layer: Multi-layer meshes inopa simba repamusoro uye kunyatsosefa asi inogona kunge yakawandisa kune mamwe maapplication.

Woven vs. Non-Woven (Fiber Felt): Nepo meshes akarukwa achipa mayunifomu pore saizi, asiri akarukwa, senge faibha akanzwa, anopa kudzika kwakadzika.

5.Consider Maintenance uye Kuchenesa:

Kangani kaunoda kuchenesa kana kutsiva sefa? Mamwe masintered meshes anogona kucheneswa kumashure, nepo mamwe angangoda kutsiviwa mushure meimwe nguva.

6. Tarisa Sefa Ratings:

Kushanda kwefiltration, kuputika kudzvanywa rating, uye permeability zviyero zvakakosha zvekufunga nezvazvo. Ita shuwa kuti mesh yakasarudzwa inosangana kana kudarika zviyero zvinodiwa zvekushandisa kwako.

7. Bvunza neVagadziri kana Nyanzvi:

Kuita ne sintered mesh sefa inogadzira kana nyanzvi inogona kupa yakakosha ruzivo. Vanogona kupa mazano chaiwo zvigadzirwa kana tsika mhinduro zvichienderana nezvaunoda.

8. Mari Inotariswa:

Kunyange zvichikosha kuti uwane sefa inoenderana nezvido zvako, zvakakoshawo kuenzana kunaka nemutengo. Funga nezvese mari yekutanga uye yenguva refu yekushandisa mari.

9. Zvitupa uye Hunhu Husimbiso:

Ita shuwa kuti mugadziri anoteedzera kumhando yepamusoro senge ISO certification. Izvi zvinovimbisa kuvimbika uye kushanda kweiyo sintered mesh mafirita.

Nekunyatsoongorora zvaunoda uye kubvunzana nenyanzvi, unogona kusarudza iyo chaiyo sintered mesh sefa inova nechokwadi chekusefa uye kurarama kwenguva refu.

Sintered melt Mesh sefa vs Sintered porous metal sefa?

Sintered melt mesh mafirita uye sintered porous simbi mafirita anoshanda zvakasiyana zvinangwa, kunyangwe ese ari maviri achigadzirwa kuburikidza nekuita sintering.

Sintered Melt Mesh Filters:

*Chimiro: Inoumbwa newaya dzesimbi dzakarukwa dzinobatanidzwa pamwechete kuita mesh.

*Kushandisa: Inonyanya kushandiswa kusefa kwezvimedu zvakakura uye senzira yekutsigira kune mamwe masisitimu ekusefa.

*Kukura kwePore: Kazhinji inopa mahombe pore saizi akakodzera kune yakakora kusefa.

*Simba: Inopa simba rakanaka remagetsi uye rinowanzo shandiswa mumashandisirwo uko kusimba kwakakosha.

Sintered Porous Metal Filters:

*Chimiro: Yakagadzirwa kubva kune sintered metal powders, zvichiita kuti iwedzere yunifomu uye yakabatana pore chimiro.

*Kushandisa: Yakanakira kusefa kwakanaka uye kusefa gasi, inokwanisa kutora zvidimbu zvidiki.

*Kukura kwePore: Inogona kugadzirwa kune chaiwo pore saizi, ichibvumira kunyatso kudzora kusefa.

*Kusiyana-siyana: Inokodzera huwandu hwakawanda hwekushandisa, kusanganisira mvura uye gasi kusefa mumaindasitiri akasiyana.

Muchidimbu, sarudzo pakati pezviviri zvinoenderana nezvinodiwa zvekusefa, senge saizi yechikamu, kuyerera kwemazinga, uye rudzi rwekushandisa.

Pano isu tinogadzira tafura yekufananidza ye sintered melt mesh mafirita uye sintered porous simbi mafirita:

| Feature | Sintered Melt Mesh Sefa | Sintered Porous Metal Sefa |

|---|---|---|

| Chimiro | Waya dzesimbi dzakarukwa dzakabatanidzwa pamwechete | Sintered metal powders |

| Application | Coarse filtration, tsigiro yepakati | Fine filtration, gasi filtration |

| Kukura kwePore | Hombe pore saizi | Yakagadzirwa kune chaiwo pore saizi |

| Simba | Simba rakanaka remagetsi | High durability uye kuramba |

| Filtration Efficiency | Kuderera kwekushanda kwezvikamu zviduku | Kubudirira kwepamusoro kune zviduku zviduku |

| Versatility | Zvishoma kune mamwe maapplication | Inokodzera maindasitiri akasiyana |

| Maintenance | Zviri nyore kuchenesa | Inogona kucheneswa uchishandisa nzira dzakawanda |

Application

Heano mamwe maapplication akakurumbira e sintered mesh mafirita, pamwe netsananguro dzakadzama kune yega yega:

1. Pharmaceutical and Biotech Production:

* Tsanangudzo: Muindasitiri yemishonga uye biotech, kuchena kwechigadzirwa kwakakosha. Sintered mesh mafirita anoita basa rakakosha mukuona kuchena uku nekubvisa tsvina uye zvinosvibisa. Iwo anoshandiswa mukushandisa senge sterile air filtration, venting, uye cell tsika midhiya kugadzirira. Zvimiro zvavo zvine inert uye kugona kuvharirwa zvinoita kuti ive yakakodzera kune izvi zvinonzwisisika zvikumbiro, kuve nechokwadi chekuenderana kwechigadzirwa uye kuchengetedzwa kwemurwere.

2. Petrochemical Processing:

* Tsanangudzo: Indasitiri yepetrochemical inogadzira zvinwiwa zvakasiyana, mazhinji acho ari viscous kana ane tsvina. Sintered mesh mafirita anonyatso patsanura zvisingadiwe zvimedu, zvichiita kuti kugadzirwa kwemafuta emhando yepamusoro, mafuta ekuzora, uye zvimwe zvigadzirwa zvemakemikari. Nekupihwa kwavo kwepamusoro-tembiricha uye kumanikidza kuramba, aya mafirita akanakirawo kunyanyisa kugadzirisa mamiriro akajairika muindastiri ino.

3. Kugadzirwa Kwekudya uye Zvinwiwa:

* Tsanangudzo: Kuve nechokwadi chehutsanana uye kuchengetedzeka kwezvinhu zvinodyiwa chinhu chinonyanya kukosha mukugadzirwa kwechikafu nechinwiwa. Sintered mesh mafirita anobatsira mukusefa kunze zvisingadiwe zvimedu, mabhakitiriya, uye zvimwe zvinosvibisa kubva kune zvinwiwa zvakaita sejusi, waini, uye manyuchi. Iwo anoshandiswawo mukufemesa maapplication kuti ive nechokwadi chekuti mweya usina kuchena unopinda mumatangi ekuvirisa kana midziyo yekuchengetedza.

4. Kurapa Mvura:

* Tsanangudzo: Kuwanikwa kwemvura yakachena kwakakosha kune zvese zvinoshandiswa uye maindasitiri maitiro. Sintered mesh mafirita anobatsira mukubvisa zvidimbu, mabhakitiriya, uye zvimwe zvinosvibisa kubva kune zvitubu zvemvura, kuve nechokwadi chemvura yekunwa yakachengeteka uye kurapwa kwemvura yemarara. Kusaita ngura kwadzo kunonyanya kubatsira pakusefa saline kana mvura ine makemikari.

5. Fluidized Bed in Chemical Processing:

* Tsanangudzo: Mibhedha yakanyungudutswa inoshandiswa mumhando dzakasiyana siyana dzemakemikari apo zvimedu zvakasimba zvinoda kumiswa mumvura. Sintered mesh mafirita anovimbisa kuyerera kwemhepo kana kuyerera kwemvura, kuve nechokwadi chekuti zvimedu zvakamiswa zvakaenzana, izvo zvakakosha pakuenderana kwemakemikari kuita uye kunaka kwechigadzirwa.

6. Aerospace uye Automotive Sefa:

* Tsanangudzo: Iyo aerospace uye maindasitiri emotokari anoda kunyatsojeka muchikamu chese, kusanganisira kusefa. Sintered mesh mafirita anoshandiswa mune hydraulic masisitimu, mafuta masisitimu, uye mashandisirwo emhepo. Kugona kwavo kumirisana nekudzvanyirira kwakanyanya uye kuramba corrosion kunoita kuti zvikoshese munzvimbo dzinonetsa idzi.

7. Electronics uye Semiconductor Manufacturing:

* Tsanangudzo: Sezvo tekinoroji ichifambira mberi, kudiwa kwemvura yakachena-yakachena uye mhepo mumagetsi uye semiconductor kugadzira kunowedzera kukosha. Sintered mesh mafirita anobatsira kuzadzisa uku kuchena nekusefa kunze sub-micron zvidimbu, kuve nechokwadi chekuti emhando yepamusoro zvinhu zvemagetsi zvinogadzirwa.

8. Mhepo Inofema muEquipment Enclosures:

* Tsanangudzo: Zvivharo zvemidziyo, senge izvo zvemagetsi emagetsi kana magiya mabhokisi, kazhinji zvinoda 'kufema' kuenzanisa kudzvanywa kana kuburitsa kupisa. Sintered mesh mafirita mumhepo yekufema inovimbisa kuti kana mweya uchipfuura, zvinosvibisa zvakaita seguruva kana hunyoro zvinochengetwa kunze, zvichidzivirira midziyo iri mukati.

Imwe neimwe yeaya maapplication anoratidza kuita kwakasiyana-siyana uye kushanda nesimba kwe sintered mesh mafirita, achisimbisa kukosha kwazvo mumaindasitiri akasiyana.

FAQ

Ndezvipi zvinhu zvakajairika zvinoshandiswa kune sintered mesh?

Zvishandiso zvakajairika zvinosanganisira simbi isina tsvina, nickel, titanium, bronze, uye akasiyana mapolymer.

Kusarudzwa kwezvinhu kunoenderana nezvinhu zvakaita sekuenderana kwemakemikari, kupikisa kwekushisa, uye simba remagetsi.

Ndezvipi zvakanakira sintered mesh mafirita?

Sintered mesh mafirita anopa akati wandei mabhenefiti, anosanganisira:

* Yakakwira porosity uye mwero wekuyerera

*Kunakisa kusefa kunyatsoshanda

* Kugara uye hupenyu hurefu hwebasa

*Kuramba corrosion uye abrasion

* Customizable pore saizi kune chaiwo maapplication

Applications

Ndeapi mamwe maapplication akajairika e sintered mesh mafirita?

Sintered mesh mafirita anoshandiswa mune dzakasiyana siyana maindasitiri, kusanganisira:

*Chemical processing

*Kugadzirwa kwemishonga

*Kugadzirwa kwechikafu nechinwiwa

*Kusefa kwezvakatipoteredza

* Aerospace uye kudzivirira

*Midziyo yekurapa

Sintered mesh mafirita anoshandiswa sei mukugadzira makemikari?

Mukugadzirisa makemikari, sintered mesh mafirita anoshandiswa ku:

*Liquid filtration kubvisa tsvina uye tsvina

*Kusefa gasi kubata zvinhu

*Catalyst rutsigiro rwekuita kwemakemikari

Kugadzira uye Zvivakwa

Sintered mesh inogadzirwa sei?

Sintered mesh inowanzogadzirwa kuburikidza nemaitiro anosanganisira:

1. Kugadzirira kwehupfu:

Metal kana polymer poda inogadzirwa neinodiwa particle size kugovera.

2.Kuumba:

Iyo poda inotsikirirwa muchimiro chaidiwa uchishandisa mold.

3.Sintering:

Iyo yakaumbwa zvinhu zvinopiswa kune yakanyanya tembiricha kuti isunge zvimedu pamwe chete, kugadzira iyo porous chimiro.

Ndezvipi zvinhu zvinokanganisa kukura kwepore uye porosity ye sintered mesh?

Iyo pore saizi uye porosity ye sintered mesh inogona kudzorwa ne:

* Saizi yechikamu:Zvimedu zvidiki zvinowanzokonzera ma pores madiki.

* Kushushikana panguva yekugadzira:Kunyanya kudzvinyirira kunogona kuderedza porosity.

*Sintering tembiricha uye nguva:Kuwedzera tembiricha uye kureba sintering nguva zvinogona kuwedzera porosity.

Iko simba remagetsi re sintered mesh rinogona kuvandudzwa sei?

Iyo mechanic simba ye sintered mesh inogona kuvandudzwa ne:

*Kushandisa chinhu chakasimba

*Kuwedzera tembiricha yekupisa

*Kuwedzera ajenti inosimbisa

Kuchengetedza uye Kuchenesa

Sintered mesh mafirita anofanira kucheneswa uye kuchengetedzwa sei?

Kucheneswa nekugadzirisa maitiro kunoenderana nechishandiso chaicho uye mhando yezvinosvibisa zviri kusefa. Nzira dzakajairika dzinosanganisira:

*Backwashing:Nekusefa kwemvura, kumanikidza iyo mvura kudzoka kuburikidza nesefa kune yakatarisana.

*Sonication:Kushandisa ultrasonic waves kubvisa zvinosvibisa kubva kune sefa pamusoro.

*Kuchenesa kemikari:Kushandisa maajenti ekuchenesa akakodzera kunyungudutsa kana kubvisa zvinosvibisa.

Ndezvipi zviratidzo zvekuti sintered mesh sefa inoda kutsiviwa?

Zviratidzo zvekuti sintered mesh sefa inoda kutsiviwa zvinosanganisira:

*Kuwedzera pressure kudonha

*Kuderera kwekuyerera

* Kukuvadza kunoonekwa kana kupfeka

*Kuderedza kusefa kunyatsoshanda

Taura nesu

Kutsvaga nyanzvi yekusefa mhinduro?

Svika kuHENGKO zvakananga paka@hengko.comkune OEM yako yakasarudzika sintered mesh mafirita.

Ngatigadzirise kunaka pamwe chete!