Sintering inoita basa rakakosha muindasitiri yekugadzira, ichigonesa kugadzirwa kwezvinhu zvakaoma uye zvinogara kwenguva refu. Kunzwisisa izvo zvakakosha zvekuimba kwakakosha kune mainjiniya, vaongorori, uye vanofarira zvakafanana. Ichi chinyorwa chine chinangwa chekunyura mune iyo pfungwa yekuimba, kuongorora maitiro ayo, kukurukura mashandisiro ayo, uye kuratidza zvakanakira uye zvinogumira.

Chii chinonzi Sintering?

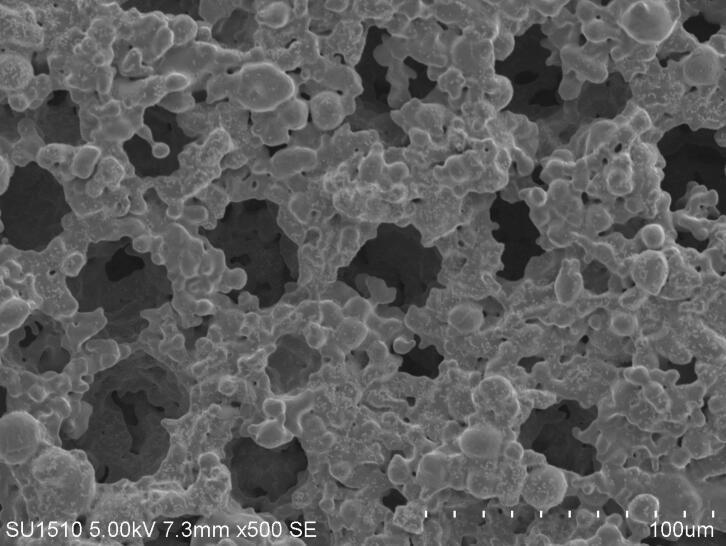

Sintering (Sintering) chirongwa chinosanganisira kubatanidza zvinhu zvehupfu kuita hurema nekuisa kupisa. Kusiyana nemaitiro echinyakare ekunyunguduka, sintering haisviki pakunyungudika kwezvinhu. Pane kudaro, inoshandisa kupararira kwemaatomu mukati mezvikamu, izvo zvinotungamira mukubatana uye densification. Iyi nzira inoguma nechimiro chakasimba nekuvandudzwa kwema mechanical properties.

Sintering inewo pfungwa yakafara uye nhete. Nekunzwisisa kwakafara, sintering inzira yekuti upfu hwakasununguka hunobatanidzwa kuita mabhuroko nesimba rakasimba rekubatanidza pane imwe tembiricha. Asi kunyura mumunda wekugadzira simbi inzira inosanganisa iron ore poda uye zvimwe zvinhu zvine iron mune yakanakisa metallurgical performance artificial block by fusion, kugadzirwa kwayo is sinter. Zvinosanganisira akasiyana physicochemical maitiro Kunyangwe ivo vese vakashandisa izwi rekuti sintering.

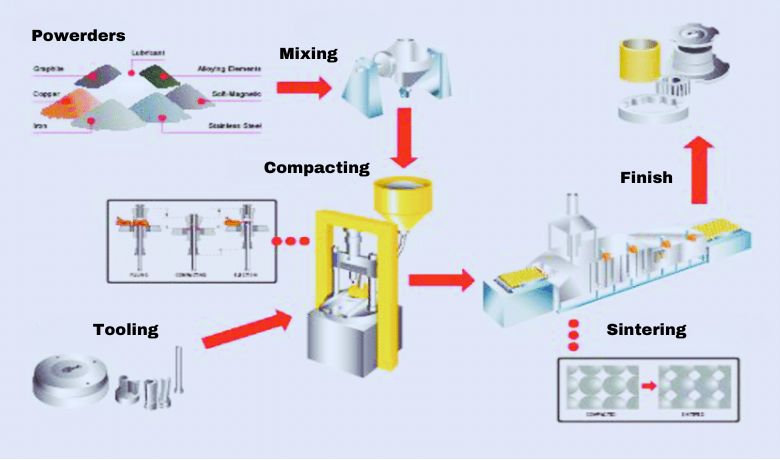

Iyo Sintering process

Iyo sintering process inosanganisira akati wandei. Pakutanga, iyo yakasvibirira inoumbwa kuita chimiro chakananga, kazhinji muchimiro chehupfu. Upfu uhu hunozopetwa pachishandiswa kudzvanywa kuti ive nechokwadi chekufanana uye kubvisa mavhodhi. Zvadaro, iyo yakasungirirwa zvinhu inoiswa pasi pekudzora kupisa muchoto chinopisa. Tembiricha inodzorwa zvakanaka kuti ifambise kusungirirana kwechidimbu pasina kukonzera kunyungudika. Munguva yekupisa, zvimedu zvinopararira, zvichiita kuti mitsipa igadzirwe uye densification. Danho rekupedzisira rinosanganisira kutonhodza chigadzirwa chakasvibiswa, chichibvumira kuti chiomese kuita chigadziko chakaoma uye chakabatana.

Hupfu hwehupfu taimboti hupfu hwesimbi kana kuti hupfu hwakatsetseka. Iyo inyanzvi yekugadzira yekuwana zvinhu kana chigadzirwa mune inodiwa masimba uye peculiarities nekuda kwemuviri uye kemikari chisungo pakati pezvimedu pane tembiricha pazasi pekunyungudika kwechinhu chikuru. HENGKO ine nhevedzano yehupfu sintering zvigadzirwa zvemhando dzakasiyana siyana uye saizi kusanganisiradisc sefa, mukombe sefa,kenduru sefa,sheet sefazvichingoenda zvakadaro. Yedu sintering Stainless simbi chigadzirwa chine mukana wekusimba kwepamusoro, Yakanaka permeability, Yakarurama filtration accuracy uye corrosion resistance, yakakodzera nzvimbo dzakawanda. Customized service inopihwawo sezvawakumbira.

Nhanho yega yega mukuita sintering ndeyekudyidzana, uye kuisa pfungwa padanho rakakosha zvakanyanya mukuita sintering, saka iyo concentrate inorevei? Concentrate inhanho inotora danho rekugadzirisa iyo mbishi nemafuta emafuta, zvichiita kuti ive mutoro wechoto unosangana ne zvinodiwa pakusimbisa kuputika kwechoto kunatsa pamberi pembishi nemafuta emafuta achipinda muchoto chinoputika. Yepamusoro tekinoroji uye yehupfumi zviratidzo uye mabhenefiti ehupfumi anogona kuwanikwa mushure meiyo concentrateis inoshandiswa mukuputika kwechoto kunyungudika. Izvo zvinonzi "shandisa zvakanyanya zvinhu zvese" uye shandisa zvakanyanya zviwanikwa. Iriwo rudzi rwekuziva kwekuchengetedza uye kuchengetedza kwezvakatipoteredza.

Zvinhu Zvinokanganisa Sintering

Zvinhu zvinoverengeka zvinopesvedzera maitiro ekupisa, kusanganisira tembiricha, chiyero chekudziya, kudzvanywa, saizi yechidimbu, uye kuumbwa. Tembiricha inoita basa rakakosha pakuona iyo sintering kinetics uye inokonzeresa zvinhu zvivakwa. Iyo yekudziya mwero inokanganisa maitiro e densification, sezvo nekukurumidza kupisa kunogona kutungamira kune isina kuenzana particle bonding. Dzvinyiriro inoiswa panguva yekumisikidzwa kuti iwedzere chidimbu chekugadzirisa uye kubvisa porosity. Saizi yechikamu uye kuumbwa kunokanganisa maitiro ekuridza, ane zvidiki zvidiki uye homogeneous nziyo dzinosimudzira zvirinani densification.

Kubva pamaonero chaiwo ezwi rekuti sintering, izwi rekuti kupisa nderokushandisa moto, panofanirwa kuve nemurazvo unoperekedzwa nekupisa kwakanyanya. Uye nzira ye sintering inofanira kuitwa mukupisa kwakanyanya. Kupisa kwepamusoro kunogadzirwa nekupisa kwehuni. Iyo tembiricha yemhando, kumhanya kwekupisa, hupamhi hwebhendi rinopfuta, mamiriro ekunze mune yakasvibiswa zvinhu, nezvimwe zvinokanganisa kufambira mberi kwekuita sintering uye kunaka kwekupedzisira sintered zvigadzirwa. Uye izvo zvinhu zvine chekuita nenyama uye makemikari zvimiro zvehuni uye dosage. Naizvozvo, iyo Yemuviri uye makemikari zvimiro zvemafuta chinhu chakakosha chinokanganisa sintering process.

Dimikira chinhu hachigone kuvapo pasina hwaro hwavanogara. Mafuta uye zvigadzirwa zvakangofanana neganda uye huni hune hukama hunokosha. Pasina chero, Iyo sintering process haigone kuitika. Asi Sintered mafuta anonyanya kureva mafuta akasimba arikutsva muchikamu chechinhu. Inonyanya kushandiswa ndeye pulverized coke powder uye anthracite, etc. Sintered mbishi zvinhu, kunyanya ine iron ore, manganese ore, zvinonyungudutsa, mafuta uye marara mumaindasitiri.

Mhando dzakasiyana dzeSintering

Sintering inosanganisira nzira dzakasiyana-siyana dzinosarudzwa zvichienderana nemaitiro uye mamiriro anobatanidzwa mukuita. Kunzwisisa mhando dzakasiyana dze sintering kwakakosha pakusarudza nzira yakakodzera kune chaiyo maapplication. Heano mamwe marudzi akajairika e sintering:

1 Solid-State Sintering

Solid-state sintering, inozivikanwawo sekuti diffusion bonding, inzira inoshandiswa zvakanyanya sintering. Mukuita uku, zvinhu zvehupfu zvinoiswa kune tembiricha yakakwira pazasi pekunyungudika kwadzo. Sezvo tembiricha inowedzera, kupararira kweatomu kunoitika pakati pezvimedu zviri pedyo, zvichiita kuti kuumbwa kwemitsipa uye kubatana. Kubviswa kwema voids uye kurongekazve kwezvikamu zvinotungamira kune densification uye kuumbwa kwesimba rakasimba.

Solid-state sintering inowanzo shandiswa mukugadzirwa kweceramics, senge porcelain uye alumina, pamwe nekunyudza simbi hupfu. Inofarirwa kana kuchengetedza makemikari kuumbwa uye kuchena kwezvinhu kwakakosha. Nekunyatso kudzora sintering paramita, senge tembiricha, nguva, uye kumanikidza, inodiwa zvinhu zvivakwa zvinogona kuwanikwa.

2 Liquid-Phase Sintering

Liquid-phase sintering inosanganisira kuwedzera kwechikamu chemvura kubatsira mukurongazve chidimbu uye chisungo panguva yekuita sintering. Chikamu chemvura, kazhinji chinenge chakaderera-chinonyungudika, chinoshanda sebhainda kana kuyerera, kuderedza tembiricha yekupisa inodiwa pa densification. Iyi nzira inonyanya kubatsira kana sintering zvinhu zvine yakakwira kunyungudika mapoinzi kana kana uchiwedzera densification rate inodiwa.

Munguva yemvura-phase sintering, chikamu chemvura chinopararira pakati pezvimedu, chichisimudzira chidimbu chekugadzirisa uye kuwedzera kuumbwa kwemutsipa uye densification. Kuvapo kwechikamu chemvura kunogonesawo kubviswa kwetsvina uye kunobatsira kunyura kwezvinhu zvine maumbirwo akaomarara.

Liquid-phase sintering inowanzoshandiswa mukugadzirwa kwecemented carbides, uko tungsten carbide particles inosungirirwa uchishandisa cobalt-based binder. Inoshandiswawo mukunyudza kwemamwe maceramics nesimbi alloys, senge simbi isina tsvina.

3 Activated Sintering

Activated sintering, inozivikanwawo se-field-assisted sintering kana spark plasma sintering, inzira yekuvandudza sintering inoshandisa simba rekunze kusimudzira densification. Inosanganisira kushandiswa kwemunda wemagetsi, magetsi emagetsi, kana mwenje wemagetsi kuti uwedzere sintering process.

Iyo yekunze simba sosi inomhanyisa kupararira kweatomu, zvichitungamira kukurumidza kuumbwa kwemutsipa uye densification. Kushandiswa kwesimba remagetsi kunogadzira kupisa kwenzvimbo, kuderedza nguva yekupisa uye kugonesa kunyura kwezvinhu pakudziya kwakadzika. Iyi nzira inopa mabhenefiti akadai sekuvandudzwa densification, kuderedzwa kwekukura kwezviyo, uye kukwidziridzwa kutonga pamusoro pe microstructure uye zvivakwa.

Activated sintering inowana zvikumbiro muminda dzakasiyana siyana, kusanganisira kugadzirwa kwemhando yepamusoro Ceramics, zvinoshanda, uye macomposites. Iyo inonyanya kubatsira kune zvigadzirwa zvine mapoinzi akanyanya kunyungudika, maumbirwo akaomarara, kana kushomeka kusingaite.

4 Mamwe Marudzi Ekuita Sinter

Kunze kwemhando dzambotaurwa, kune dzimwe dzinoverengeka dzakati wandei sintering nzira dzakagadzirirwa kune chaiwo maapplication. Izvi zvinosanganisira microwave sintering, uko simba remicrowave rinoshandiswa kupisa nekupisa zvinhu, uye kunyura-kunobatsira sintering, iyo inosanganisa kudzvanywa uye kupisa kuwedzera densification.

Pamusoro pezvo, yakasarudzika laser sintering (SLS) uye erekitironi danda sintering (EBS) nzira dzekuwedzera dzekugadzira dzinoshandisa matanda esimba kusarudza zvinhu zvine hupfu, dhizaini nedhiza, kugadzira zvinhu zvakaoma-mativi matatu.

Imwe neimwe mhando ye sintering inopa yakasarudzika mabhenefiti uye inosarudzwa zvichibva pane zvenyama zvivakwa, mhedzisiro inodiwa, uye chaiyo maapplication.

Zvikumbiro zveSintering

Sintering inowana zvikumbiro zvakakura mumaindasitiri akasiyana siyana nekuda kwekugona kwayo kushandura zvinhu zvehupfu kuita zvinhu zvakasimba zvine zvivakwa zvinowedzerwa. Ngationgororei dzimwe dzenzvimbo dzakakosha uko sintering inoshandiswa zvakanyanya:

1 - Ceramics

Ceramics ndeimwe yeminda yekutanga iyo sintering inoshandiswa zvakanyanya. Sintered ceramics inoratidza yakagadziridzwa simba remuchina, kuoma, uye kugadzikana kwekupisa. Sintering inoshandiswa mukugadzira mataira eceramic, sanitaryware, maturusi ekucheka, zvigadziriso zvemagetsi, uye magetsi anodzivirira. Nekunyatso kudzora sintering paramita, ceramic zvinhu zvinogona kuwana inodiwa density, porosity, uye microstructure kune chaiwo maapplication.

2 - Metallurgy

Mune metallurgical applications, sintering inoshandiswa kugadzira zvakasiyana-siyana zvezvikamu zvesimbi. Izvi zvinosanganisira magiya, mabhengi, bushings, zvikamu zvemotokari, uye zvimiro zvemukati. Metal poda, senge simbi, aruminiyamu, uye simbi isina simbi, inoumbwa nekunyungudutswa kuti ibudise mativi akasimba ane michina yakanaka. Sintered metal components zvinowanzoratidza simba repamusoro, kupfeka kuramba, uye kurongeka kwedimensional zvichienzaniswa neyakakandwa zvikamu.

3 - Composites

Sintering inotora basa rakakosha mukugadzirwa kwezvinhu zvinosanganiswa, uko maviri kana anopfuura akapatsanurwa zvinhu zvinosanganiswa kugadzira zvinhu zvine zvivakwa zvakawedzerwa. Mukugadzira simbi matrix composites (MMCs) uye ceramic matrix composites (CMCs), sintering inoshandiswa kubatanidza zvinhu zvekusimbisa, senge fiber kana zvimedu, ine matrix zvinhu. Izvi zvinowedzera kusimba, kuomarara, uye kuomarara kwezvinobuda zvakaumbwa zvinhu.

4 - Upfu Metallurgy

Powder metallurgy, bazi rakasarudzika resimbi, rinotsamira zvakanyanya pakupisa. Inosanganisira kugadzirwa kwezvinhu zvesimbi kubva muupfu hwesimbi. Kuburikidza nemaitiro akaita semakochekera uye sintering, zvikamu zvakaoma kunzwisisa zvine maumbirwo akaomarara zvinogona kugadzirwa. Powder metallurgy inowanzoshandiswa muindasitiri yemotokari kugadzira magiya, camshafts, uye zvigaro zvevharuvhu, pamwe nekugadzira maturusi ekucheka uye mafirita akachekwa.

5 - 3D Printing / Additive Manufacturing

Sintering inotora basa rakakosha mukuwedzera kugadzira matekiniki akadai seselective laser sintering (SLS) uye electron beam sintering (EBS). Mune maitiro aya, zvinhu zvehupfu zvinosarudzwa zvakanyungudutswa nedhizaini, zvichibva padhizaini yedhijitari, kugadzira zvinhu zvakaoma-matatu-dimensional. Sintering inobvumira kubatanidzwa uye kusungirirwa kwehupfu hwehupfu, zvichiita kuti zvikamu zvakazara uye zvinoshanda. Iyi tekinoroji inoshandiswa mumaindasitiri akasiyana siyana, kusanganisira aerospace, hutano hwehutano, uye prototyping.

6 Electronics uye Electrical Engineering

Sintering inoshandiswa mukugadzira zvinhu zvemagetsi nemagetsi. Mukugadzirwa kwemagetsi ekeramics, senge capacitors, varistors, uye thermistors, sintering inoshandiswa kubatanidza zvimedu zveceramic, kugadzira dense uye magetsi conductive zvinhu. Sintering inoshandiswawo mukugadzira magetsi anobatika, semiconductor packaging, uye wedunhu bhodhi zvikamu.

Iyi ingori mienzaniso mishoma yemashandisirwo akasiyana ekuita sintering. Iyo nzira iri kuramba ichiongororwa nekukwenenzverwa kuti isangane nezvido zvinoshanduka zvemaindasitiri akasiyana, zvichiita kuti kugadzirwa kwezvinhu zvepamusoro-soro uye zvikamu.

Zvakanakira Sintering

Sintering inopa akawanda mabhenefiti anoita kuti ive yakasarudzika nzira yekugadzira mumaindasitiri akasiyana. Ngationgororei zvimwe zvakakosha zvakanakira:

1 Maumbirwo Akaoma uye Akaomesesa Dhizaini

Imwe yemabhenefiti akakosha ekuita sintering kugona kwayo kugadzira zvinhu zvine maumbirwo akaomarara uye akaomarara dhizaini. Nekushandisa zvinhu zvine hupfu, sintering inobvumira kuumbwa kwezvikamu zvine akaomesesa geometries izvo zvingave zvakaoma kuwana uchishandisa echinyakare machining matekiniki. Uku kuchinjika mukuumbwa kunogonesa kugadzirwa kwezvinhu zvakagadziridzwa zvakagadzirirwa kune chaiwo maapplication.

2 Mechanical Properties Yakavandudzwa

Sintering inokwidziridza ma mechanical zvimiro zvezvinhu, zvichikonzeresa kuti zvikamu zvine hunhu hwepamusoro hwekuita. Munguva yekugadzira sintering, zvimedu zvinosunga uye kusimba, zvichitungamira kusimba rakavandudzwa, kuomarara, uye kupfeka kuramba kwechigadzirwa chakasvibiswa. Iyo inodzorwa yekudziya uye yekuparadzira masisitimu inosanganisirwa mukuita sintering inobatsira mukuvandudzwa kweyakaomesesa uye yakabatana chimiro, inosimudzira iyo yakazara mechanical kutendeseka kwechikamu.

3 Zvinoenderana Nezvinhu Zvinoumbwa

Sintering inobvumira kubatanidzwa kwehupfu nemhando dzakasiyana-siyana, zvichiita kuti kugadzirwa kwezvinhu zvine maitiro akagadzirirwa. Nekusanganisa mhando dzakasiyana dzehupfu kana kubatanidza zvinowedzerwa, zvinokwanisika kugadzirisa hunhu hwechinyorwa zvinoenderana nezvinodiwa chaizvo. Uku kuchinjika mukuumbwa kunovhura mikana yekugadzira zvigadzirwa zvepamberi zvine optimized performance, senge yakakwirira-simba alloys kana zvinhu zvine chaiwo magetsi kana ekupisa.

4 Mutengo-Kubudirira

Sintering inzira inodhura yekugadzira kana ichienzaniswa neyechinyakare kunyungudika uye kukanda maitiro. Kushandiswa kwehupfu hwehupfu kunoderedza tsvina yezvinhu, sezvo yakawandisa poda inogona kuunganidzwa uye kushandiswa zvakare. Pamusoro pezvo, iyo sintering process inoda yakaderera simba rekushandisa sezvo ichishanda patembiricha pazasi pekunyungudika kwezvinhu. Iko kugona kugadzira zviri pedyo-net-shape zvikamu zvinowedzera kuderedza kudiwa kweanotevera machining mashandiro, zvichikonzera kuchengetwa kwemutengo maererano nekushandiswa kwezvinhu, kushandiswa kwesimba, uye post-kugadzirisa.

5 Kusiyana-siyana Pakusarudza Zvinhu

Sintering inopa kuita kwakasiyana-siyana mukusarudza kwezvinhu, kugadzika huwandu hwakasiyana hwezvinhu zvekushandisa kwakasiyana. Iyo yakakodzera kune ceramics, simbi, uye kompositi. Mhando dzakasiyana dzezvishandiso, zvinosanganisira oxides, carbides, nitrides, uye alloys, anogona kugadziriswa kuburikidza sintering. Uku kuenderana kwezvinhu zvakakura kunobvumira kugadzirwa kwezvakasiyana zvikamu zvine chaiwo zvinhu zvemukati, zvichiita kuti sintering ive sarudzo inoyevedza kune akawanda maindasitiri.

Zvakanakira Sintering mukuumbwa kwakaomarara, kuvandudzwa kwemakanika zvivakwa, zvakagadzirirwa zvinhu zvinyorwa, mutengo-unoshanda, uye zvinhu zvakasiyana-siyana zvinoita kuti ive yakakosha kugadzira maitiro muzvikamu zvakasiyana. Nekushandisa mabhenefiti aya, maindasitiri anogona kuwana kugadzirwa kwakanaka, kukwidziridzwa kwekuita, uye kuchengetedza mutengo mukugadzira kwavo maitiro.

Kune zvakawanda zvekuchinja kunosanganisira kuoma kwemuviri nemakemikari shanduko. Kuita kwenyama uye kemikemikari muupfu kunyura kunosanganisira kubuda kana kubuda kwemvura kana organic zvinhu, kubviswa kwemagasi adsorbed, kudzikiswa kwekushushikana, kuderedzwa kwemaokisi epamusoro ehupfu, kutama kwezvinhu, kugadzirwazve, kukura kwezviyo, nezvimwewo. Zvakakosha kudzidza. uye kunzwisisa ruzivo rwekuimba semugadziri. Uye semutengi, kudzidza idzi ruzivo rwekutanga kunogona kutigonesa kuve nezano rakanaka pakusarudza zvigadzirwa zve sintering.

Sintering inzira yechinyakare uye yakaoma. Nguva dziri kufambira mberi, Uye tekinoroji yekugadzira uye michina yekugadzira zvakare inogadziridzwa nguva dzose. Chengetedza ruzivo rwekutanga uye dzidza ruzivo rutsva rwakakosha kune vashandi vane chekuita neindasitiri. Kwemakore gumi nemasere apfuura.HENGKOinogara ichiomerera pakugara ichizvinatsiridza pachayo, ichipa vatengi zvigadzirwa zvakanaka uye masevhisi ane hanya, kubatsira vatengi uye budiriro yakafanana. Tinovimba kuva shamwari yako yakavimbika kwenguva refu.

FAQs (Mibvunzo Inowanzo bvunzwa)

Ndezvipi zvinhu zvinogona kubikwa?

Yakasiyana-siyana yemidziyo inogona kucheneswa, kusanganisira ceramics, simbi, uye makombiji. Mienzaniso inosanganisira hupfu hweceramic sealuminium uye zirconia, hupfu hwesimbi sesimbi uyesintered Stainless steel filters, uye poda dzakaumbwa dzine zvinhu zvekusimbisa zvakaita sefiber kana zvidimbu.

Ndezvipi zvakanakira sintering zvichienzaniswa nedzimwe nzira dzekugadzira?

Sintering inopa akawanda mabhenefiti pamusoro pechinyakare nzira dzekugadzira. Inobvumira kugadzirwa kwezvikamu zvine maumbirwo akaomarara uye akaomesesa dhizaini, inopa yakagadziridzwa michina zvimiro, inogonesa kugadziridzwa kwezvinyorwa zvemukati, inodhura-inoshanda nekuda kwekuderedzwa kwemarara emidziyo, uye inogadzika zvakasiyana siyana zvekushandisa zvakasiyana.

Ndeapi maapplications makuru e sintering?

Sintering inowana zvikumbiro mumaindasitiri akadai seceramics, metallurgy, poda metallurgy, zvemagetsi, uye zvekuwedzera kugadzira. Inoshandiswa kugadzira mataira eceramic, zvikamu zvemotokari, zvikamu zvesimbi, maturusi ekucheka, makeramiki emagetsi, uye 3D-yakadhindwa zvinhu, pakati pezvimwe.

Pane zvipimo here kana zvipingamupinyi ne sintering?

Sintering ine zvimwe zvinogumira uye zvinonetsa. Kuwana yunifomu densification mukati mezvinhu zvese zvinogona kunetsa, sezvo kusaenzana kupisa kana kugovera kwechidimbu kunogona kukonzera kukanganisa. Kudzora kukura kwezviyo uye kudzivirira kuderera kwakanyanya panguva yekunyura zvakare zvakakosha kufunga. Pamusoro pezvo, hazvisi zvese zvishandiswa zvakakodzerwa nekunyunguduka nekuda kwenzvimbo dzazvo dzekunyungudika kana reactivity nemhepo yakatenderedza.

Ndeapi marudzi akasiyana ehunyanzvi hwekuita sintering?

Kune marudzi akasiyana-siyana ehunyanzvi hwekuita sintering, anosanganisira solid-state sintering, liquid-phase sintering, activated sintering, microwave sintering, pressure-assisted sintering, pamwe nehunyanzvi hwekuita se selective laser sintering (SLS) uye electron beam sintering (EBS). Imwe neimwe tekinoroji ine maitiro ayo akasiyana uye inosarudzwa zvichienderana nezvinodiwa zvechinyorwa uye mashandisiro.

Sintering inovandudza sei zvinhu zvezvinhu?

Sintering inovandudza zvimiro zvemidziyo nekusimudzira particle bonding uye densification. Munguva yekugadzira sintering, zvimedu zvinopararira, zvichiita kuti pave nekuumbwa kwemutsipa uye kuwedzera kuwanda. Izvi zvinoguma nekuvandudzwa kwemechanicha zvinhu senge simba, kuomarara, uye kupfeka kuramba. Pamusoro pezvo, sintering inogona kutungamira mukuvandudzwa kwemagetsi, kupisa, uye makemikari zvimiro zvinoenderana nechinhu uye kuumbwa kwayo.

Zvikamu zve sintered zvinogona kugadzirwa kana kugadziridzwazve?

Ehe, sintered zvikamu zvinogona kuwedzererwa kugadzirisa kana machining, kana zvichidikanwa. Nepo sintering inogona kuwana padhuze-net-shape zvikamu, panogona kunge paine zviitiko apo kuwedzera machining kana post-kugadzirisa kuchidikanwa kuti uwane izvo zvinodiwa. Machining maitiro sekugaya, kuchera, kana kukuya anogona kushandiswa kuzadzisa zviyero zvekupedzisira kana kupera kwepamusoro.

Ndezvipi zvakatipoteredza zvekufunga nezve sintering?

Sintering inowanzoonekwa seyakagadzikana yekugadzira maitiro. Inopedza simba shoma kana ichienzaniswa nekunyunguduka uye nzira dzekukandira, uye inoderedza tsvina yezvinhu nekubvumira kushandiswazve kwehupfu hwakawandisa. Nekudaro, zvakakosha kuti titarise kukanganisa kwezvakatipoteredza kwezvakagadzirwa zvinoshandiswa, pamwe nekubata kwakanaka uye kuraswa kwechero byproducts kana tsvina inogadzirwa panguva yekuita.

Sintering inobatsira sei mukugadzirwa kwezvinhu zvepamberi?

Sintering inoita basa rakakosha mukugadzirwa kwezvinhu zvepamberi. Nekunyatsosarudza uye kudzora kuumbwa, particle size, uye sintering parameters, zvinokwanisika kugadzirisa zvimiro zvezvakaguma. Izvi zvinobvumira kugadzirwa kwezvinhu zvepamberi zvine hunhu chaihwo, hwakadai seyepamusoro-inoshanda alloys, inoshanda ceramics, kana komputa zvinhu zvine akasiyana musanganiswa wezvivakwa.

Kana iwe uine mimwe mibvunzo kana uchida kuti ubate nayoHENGKO,

ndapota inzwa wakasununguka kutibata nesu kuburikidza neemail paka@hengko.com.

Tingafara kukubatsira uye nekupa chero rumwe ruzivo rwaungade.

Nguva yekutumira: Aug-14-2020