-

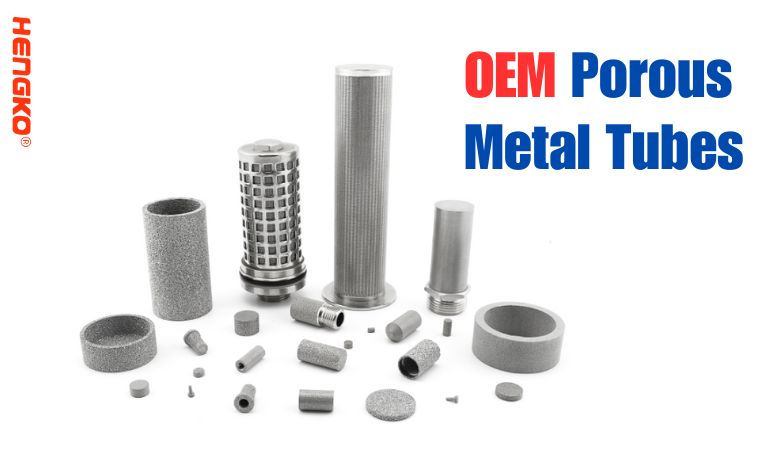

Simbi Isina Sintered Porous Metal Sefa Machubhu Porosity Kudzika kusvika 0.2 µm - MuF...

Pore saizi: 0.2-100microns Zvishandiso: SS Metal Porosity: 30% ~ 45% Kudzvinyirira Kushanda: 3MPa Kushanda Tembiricha: 600 ℃ Zvikumbiro zve sintered porous metal ...

View Detail -

Kutsiva Micro-Bubble Porous Sparger Mazano eKuvirisa / Bioreactor Mhepo Aeration...

Zvakanakira zveHENGKO Porous Metal Micro Spargers Nekuda kwekudzikira kunyungudika kweokisijeni mumasero akawanda tsika masvikiro, kukwirisa ichi chakakosha chikafu chinogona ...

View Detail -

Stainless Simbi Tubeless Tire Valve Yakasimba Uye Yakasimba Tire Valve Short Rod YeMota Tru...

Zvigadzirwa Tsanangudzo Ivhavha iyi yakazvimiririra yevhavha yemuviri mudziyo inobvumira gasi kupinda munzvimbo ye tubeless tire kana chubhu kana yavhurwa, uyezve ...

View Detail -

Wholesale Wire Mesh Sefa Stainless Simbi 10 Micron Sintered Tube YeMushonga M...

Mafirita esimbi asina simbi akanakira kushandiswa mukudiwa kweinjiniya zvinoda kusefa mumamiriro ezvinhu akashata, sejet en...

View Detail -

Sintered Porous Metal Stainless Steel Filter Tube yeFiber Optic Collimator HENGKO

Chigadzirwa Rondedzera porous metal cartridges inogona kugadzirwa kune akasiyana siyana mashandisirwo uye yakatarwa uye inogona kusungirirwa kune simbi uye isiri-meta...

View Detail -

Yakanyanya Kurongeka Yakaderera Kushandisa I2C Chimiro Tembiricha & Humidity hama Sensor...

HENGKO tembiricha uye humidity sensor probe yakagadzirwa neiyo IP66 yekudzivirira giredhi yakakwirira-yakasimba simbi isina tsvina sensor porous dzimba, inogona kushandiswa zvakananga...

View Detail -

tembiricha uye hunyoro humidity sensor probe ine simbi isina tsvina yekuwedzera chubhu uye ...

Iyo HT-E067 hunyoro hunyoro/ tembiricha transmitter inopa yakavimbika uye yakaderera-mutengo nzira ye duct mount monitoring application. Solid-state sensors pr...

View Detail -

Sintered Sparger Tube ine Porous Metal Stainless Simbi Tangi uye In-line Spargers Anoshandiswa ...

Kuunza yakasarudzika HENGKO sintered spagers, mhinduro yekupedzisira kuunza magasi muzvinwiwa. Ichi chigadzirwa chitsva chinoshandisa zviuru zve...

View Detail -

High performance porous sintered simbi isina tsvina isostatic machubhu machubhu anotsigira ...

Stainless simbi sintered machubhu anogadzirwa nestainless simbi poda, inogadziriswa ne sintering tekinoroji. Ichi chigadzirwa chinogona kuchenesa midhiya yakasvibiswa uye kubudirira ...

View Detail -

Hydrogen yakapfuma mvura muchina - sintered SS 316L Stainless simbi 0.5 2 micron mhepo o ...

Mvura yeHydrogen yakachena, ine simba, uye ine hydron. Inobatsira kuchenesa ropa uye inoita kuti ropa rifambe. Inogona kudzivirira marudzi mazhinji ezvirwere uye kugadzirisa vanhu ...

View Detail -

Yakaiswa Yakananga Porous Metal In-Line Sparger Tube Gadzira Diki Mabhuru

HENGKO sintered spagers inopinza magasi muzvinwiwa kuburikidza nezviuru zvema pores madiki, ichigadzira mabhuru madiki uye akawanda kupfuura ane pombi yakacherwa ...

View Detail -

316L simbi isina tsvina porous simbi yakatwasuka sefa chubhu yakaita sparging magungano

Sintered air stone diffusers inowanzoshandiswa kune porous gasi jekiseni. Vane hukuru hwakasiyana hwepore (0.5um kusvika 100um) inobvumira mabhuru madiki kuyerera nemu ...

View Detail -

316L simbi isina tsvina porous sparger chubhu sintered tipi yekuvirisa mudziyo wemidziyo

Inonamatira kumuromo wesparger chubhu, iyi 316L simbi isina sintered tip inowanikwa mumhando dzakasiyana dzepore. Iyo 5 10 15 50 100 pore frit ndiyo ...

View Detail -

Cylindrical 25 50 micron Stainless simbi microns porous powder sintered filter chubhu ye...

HENGKO Stainless simbi sefa machubhu anogadzirwa ne sintering 316L poda zvinhu kana multilayer Stainless simbi waya mesh pakupisa kwakanyanya. Ivo vanga vari ...

View Detail -

Porous simbi sefa chubhu yekupisa manejimendi kunatsa uye yakakosha kemikari | HENGKO

HENGKO Stainless simbi sefa machubhu anogadzirwa ne sintering 316L poda zvinhu kana multilayer Stainless simbi waya mesh pakupisa kwakanyanya. Ivo vanga vari ...

View Detail -

Nyanzvi mugadziri akagadziridzwa sintered porous simbi sefa chubhu inoshandiswa pakurapa...

HENGKO sintered mafirita anowanzo shandiswa kucheneswa uye kusefa kwemvura uye gasi, kupatsanurwa uye kudzoreredzwa kwezvimedu zvakasimba, kufefetedza kutonhora...

View Detail -

0.2um kusvika 90 micron 5 - 100mm kureba hupfu kana waya mesh porous sintered simbi sta ...

HENGKO Stainless simbi sefa machubhu anogadzirwa ne sintering 316L poda zvinhu kana multilayer Stainless simbi waya mesh pakupisa kwakanyanya. Ivo vanga vari ...

View Detail -

Sintered simbi poda porous 316l SS Stainless simbi sefa chubhu, 2 μm 5 7 10 15 20 30 ...

HENGKO Stainless simbi sefa machubhu anogadzirwa ne sintering 316L poda zvinhu kana multilayer Stainless simbi waya mesh pakupisa kwakanyanya. Ivo vanga vari ...

View Detail -

2 10 20 25 microns porous SS 304/316L simbi sintered Stainless simbi sefa chubhu nokuda li...

HENGKO Stainless simbi sefa machubhu anogadzirwa ne sintering 316L poda zvinhu kana multilayer Stainless simbi waya mesh pakupisa kwakanyanya. Ivo vanga vari ...

View Detail -

Sintered simbi 316 Stainless simbi sefa yekurapa micro filter chubhu yemvura uye gasi ...

Chigadzirwa Rondedzera Porous sefa zvinhu zvakashandiswa zvakanyanya mumetallurgical, makemikari, mishonga, aerospace, uye minda yendege. Porous Metal media...

View Detail

Sei Uchishandisa Porous Metal Tube?

Pane zvikonzero zvikuru zvakati kuti neisintered simbi chubhuanoshandiswa mune zvakasiyana-siyana zvekushandisa:

Sefa:

* Basa ravo guru nderokusefa. Iyo chaiyo inodzorwa pore saizi inovabvumira kubvisa tsvina,

zvidimbu, uye zvinosvibisa zvinobva mumvura nemagasi. Izvi zvinogona kukosha mumaindasitiri akaita semishonga,

kugadzirwa kwemakemikari, uye chikafu nechinwiwa, uko kuchena kwakakosha.

* Saizi yePore inogona kubva pasubmicron kusvika kumamirimita akati wandei, ichivagonesa kusefa kwakasiyana siyana masaizi.

Kuyerera Kunodzorwa:

* Iyo porous chimiro inobvumira kudzora kuyerera kwezvinwiwa uye magasi.

Izvi zvinogona kushandiswa kuaeration, kugovera gasi, fluidization, uye mamwe maapplication apo kunyatso kudzora kuyerera kunodiwa.

* Iyo yunifomu pore kugovera inovimbisa kutenderera kuyerera mukati mechubhu, kudzivirira kutenderera uye kusaenzana kwekumanikidza kugovera.

Durability uye Simba:

* Yakagadzirwa nesimbi yakaita sesimbi isina tsvina, nickel, kana bhuronzi, porous metal chubhu inogara yakasimba uye inogona kumira kushanda nesimba.

mamiriro ezvinhu, kusanganisira tembiricha yakakwira, kumanikidzwa, uye nharaunda dzine ngura.

* Izvi zvinovaita kuti vakwanise kushandiswa kwenguva refu mukudiwa kwemaindasitiri.

Zvimwe zvinobatsira:

* Porous metal chubhu zvakare akareruka, anocheneswa zviri nyore, uye anogona kushandiswazve. Vanogona kugadzirwa nyore nyore uye kuumbwa mumhando dzakasiyana siyana,

zvichiwedzera kuwedzera kugona kwavo kwakasiyana-siyana.

Heano mimwe mienzaniso chaiyo yemashandisirwo apo porous simbi machubhu anoshandiswa:

* Mhepo diffuser:mumiti yekuchenesa mvura yetsvina kuunza oxygen mumvura yekukura kwebhakitiriya.

* Mafirita emafuta:mumotokari nedzimwe motokari kubvisa tsvina mumafuta.

* Maimplants ekurapa:yekupinza mapfupa uye kuendesa zvinodhaka.

* Catalyst inotsigira:mune makemikari reactors kubata uye kugovera catalysts.

* Silencers:mune exhaust systems kuderedza ruzha.

Pakupedzisira, zvikonzero chaizvo nei mumwe munhu angasarudza porous simbi chubhu zvinoenderana nechaiyo application

nezvinodikanwa zvayo. Nekudaro, yavo yakasarudzika musanganiswa wekusefa, inodzorwa kuyerera, kusimba, uye mamwe mabhenefiti

zviite chishandiso chakakosha kune akasiyana maindasitiri.

Main Function

Thesintered simbi chubhurinenge basa rakafanana nemamwesintered metal filters or sintered metal sparger.

Basa guru reporous simbi machubhu nderokupa inoshanda uye yakavimbika kusefa, kupatsanura, uye kutonga

yekuyerera kwemvura uye gasi.

Aya machubhu esimbi ane porous anogadzirwa kubva kumhando 316L SS simbi zvimedu zvinosanganiswa pamwechete kuburikidza ne sintering.

maitiro, kugadzira chimiro chine maburi akabatana. Iwo akasiyana maitiro e porous simbi machubhu

vagonese kushanda akati wandei akakosha mabasa:

1. Sefa:

Chinangwa chekutanga cheporous metal chubhu kuita semasefa, kubvisa tsvina, zvidimbu, uye zvinosvibisa kubva mumvura nemagasi.

Iko kunyatso kudzora kwehukuru hwepore inovatendera kuti vakwanise kusefa yakadzika kusvika kune submicron mazinga, kuve nechokwadi kuchena kwepakati iri kugadziriswa.

2. Gasi uye Kuparadzirwa kwemvura:

Porous simbi chubhuanoshandiswa kuparadzira magasi kana zvinwiwa zvakaenzana uye zvakafanana. Nekudzora saizi yepore uye kugovera,

vanogona kugadzira yunifomu yekuyerera pateni, kudzivirira kutenderera uye kuvandudza kupararira kwekubudirira.

3. Fluidization:

Mumibhedha yakanyunguditswa, machubhu aya anoshandiswa kunyorovesa zvimedu zvakasimba, zvichigadzira yakamiswa-yakaita semvura.

Iyo yunifomu yekugovera ye pores inobatsira mukubudirira uye inodzorwa fluidization.

4. Venting uye Pressure Equalization:

Porous simbi machubhu anoshandiswa kuburitsa magasi, kuenzana kumanikidza, kana kudzoreredza vacuum mamiriro mune akasiyana masisitimu.

nemidziyo. Vanogonesa kufamba kwemhepo kana gasi uku vachidzivirira kupinda kwezvinosvibisa.

5. Kuderedza ruzha:

Mune mamwe maapplication, porous simbi machubhu anoshandiswa sesilencer kana mufflers kuderedza ruzha runokonzerwa nekuyerera kwemagasi kana mvura.

6. Kupararira:

Porous simbi machubhu anofambisa gasi kana mvura diffusion maitiro nekubvumira mamorekuru kupfuura nepamapores awo akabatana.

Ichi chivakwa chinowana application munzvimbo dzakasiyana siyana, senge catalysis uye misa yekufambisa mabasa.

7. Tsigiro uye Kugovera:

Mune mamwe maindasitiri, porous simbi machubhu anoshanda sezvimiro zvekutsigira zvinokonzeresa kana zvimwe zvinhu, zvichipa yakagadzikana.

framework uye kubatsira mukugovera yunifomu.

Nekuda kwekukwirira kwazvo, kusimba, kuramba kwemakemikari, uye zvimiro zvepore zvinodzoreka, porous simbi machubhu anowana yakakura.

shandisa mumaindasitiri akadai semishonga, petrochemicals, kurapwa kwemvura, mota, aerospace, nezvimwe zvakawanda,

uko kusefa kwakanaka uye kudzorwa kuyerera maitiro kwakakosha pakuita kwakanyanya uye kuchengeteka.

Kushanda Nheyo yeSintered Porous Metal Tubes

Iyo yekushanda musimboti we sintered porous simbi machubhu yakavakirwa pane yakasarudzika zvimiro zvesintered simbi chimiro,

iyo inobvumira kusefa kwakanaka uye kudzorwa kuyerera kwemvura nemagasi. Heino mhedziso yenheyo yekushanda:

1. Sintering process:

Porous metal chubhu inogadzirwa nenzira inonzi sintering. Zvinosanganisira kubatanidza simbi zvidimbu, kazhinji

Stainless simbi kana mamwe simbi alloys, mune chaiyo chimiro, senge chubhu. Zvimedu zvesimbi zvinopisa kusvika kune tembiricha

pazasi penzvimbo yavo yekunyungudika, zvichiita kuti vabatane pamwechete, vachigadzira network yakasimba uye yakabatana yemapores.

2. Pore Structure:

Iyo sintered simbi machubhu ine yakatsanangurwa pore chimiro nekuda kwekurongeka kwesimbi zvidimbu panguva yekupisa.

Saizi, chimiro, uye kugovera kweaya ma pores anogona kunyatso kudzorwa panguva yekugadzira kuti isangane nezvinodiwa zvekusefa.

3. Sefa:

Basa rekutanga re sintered porous metal chubhu is filtration. Kana mvura kana gasi richipfuura nemuchubhu, zvinosvibisa,

zvidimbu, uye tsvina inotorwa mukati me pores. Saizi yepore yakagadzirirwa kubvumira mvura yaunoda kana gasi kupfuura

uku uchivharisa zvinhu zvisingadiwe.

4. Kusefa Kubudirira:

Iko kusefa kwakanaka kwe sintered porous simbi machubhu kunoenderana nehukuru hwepore uye yakazara nzvimbo yepasi inowanikwa yekusefa.

Madiki pore saizi anogona kutora akakwenenzverwa zvimedu, achipa yakakwirira kusefa kunyatsoita.

5. Kudzora Kuyerera:

Iyo yakabatana pore chimiro che sintered simbi machubhu inogonesa kutonga chaiko pamusoro pemvura kana gasi kuyerera. Saizi uye

kuparadzirwa kwepores kunokanganisa kuyerera kwehuwandu uye kudonha kwemhepo kudonhedza chubhu. Ichi chivakwa chakakosha mumashandisirwo

uko yunifomu yekuyerera kugovera kana kudzorwa fluidization kunodiwa.

6. Kugara uye Kuramba:

Sintered simbi machubhu akasimba uye anoshingirira kune mechaniki kusagadzikana, makemikari, uye tembiricha yepamusoro. The sintering

hurongwa hunova nechokwadi chekuti simbi zvidimbu zvakasungwa zvakasimba, zvichipa kutendeseka kwemaitiro kunyange pasi pemamiriro ekushanda akaoma.

7. Reusability uye Kucheneswa:

Sintered porous metal chubhu inogona kucheneswa zviri nyore uye kushandiswa zvakare. Vanogona kumira nzira dzakasiyana dzekuchenesa,

senge backwashing, ultrasonic kucheneswa, kana kuchenesa makemikari, pasina kukanganisa kugona kwavo kusefa.

Nheyo yekushanda ye sintered porous metal chubhu inoita kuti ive yakawanda uye inokodzera huwandu hwakawanda hwe

mashandisirwo mumaindasitiri akadai sepetrochemicals, mishonga, kurapwa kwemvura, aerospace, nezvimwe. Vari

vakasarudzwa kuitira kusefa kwavo kwakanaka, kusimba, uye kugona kumira munzvimbo dzakaoma, vachipa kuita kwakavimbika

mune zvakakosha maitiro uye masisitimu.

Chii Chaunofanirwa Kuchengeta OEM Porous Metal Tubes?

Kana uchifunga nezveOEM yakakosha porous simbi machubhu kune yako filtration system kana mapurojekiti, kune akati wandei

zvinhu zvakakosha zvekufunga nezvazvo kuti ive nechokwadi chekuita kwakakwana uye kuita kwakabudirira.

Heano mamwe makuru ekufungisisa:

1. Sefa Zvinodiwa:

Tsanangura zvakajeka zvinodikanwa zvekusefa zvekushandisa kwako. Sarudza yaunoda kusefa kunyatsoshanda,

pore saizi, uye mwero wekuyerera unodiwa kuti uwane mhedzisiro inodiwa.

2. Fluid kana Gasi Hunhu:

Nzwisisa zvimiro zvemvura kana gasi rinofanira kusefa, kusanganisira tembiricha, kudzvanywa, viscosity, uye kemikari

kugarisana. Ita shuwa kuti iyo yakasarudzwa porous simbi zvinhu inogona kumirisana nezvinodiwa zvekushanda mamiriro.

3. Kukura kwePore uye Chimiro:

Shanda nemugadziri weOEM kugadzirisa saizi yepore uye chimiro cheporous metal chubhu kuti ienderane neyako

zvinoda application. Funga nezvekukura kwechidimbu chezvinosvibisa kuti zvibviswe uye hunhu hunodiwa hwekuyerera.

4. Kusarudzwa kwezvinhu:

Sarudza iyo yakakodzera simbi zvinhu zvichibva pane yayo makemikari kuramba, michina zvimiro, uye kuenderana nayo

svikiro iri kusefa. Zvishandiso zvakajairika zvinosanganisira simbi isina tsvina, bhuronzi, nickel, uye titanium.

5. Dhizaini uye Geometry:

Bata pamwe nemugadziri weOEM kugadzira chimiro nehukuru hwechubhu kuti ikwane system yako kana purojekiti.

Funga zvinhu zvakadai sehurefu, dhayamita, uye magumo ekubatanidza kuitira nyore kubatanidza.

6. Kushanda Kwesefa uye Kudonhedza Kwekumanikidza:

Balance kufefetera zvakanaka nekudzvanywa kudonha kuyambuka porous metal chubhu. Yepamusoro kusefa kunyatsogona

kutungamira mukudonha kwekumanikidza, izvo zvinogona kukanganisa maitiro ehurongwa.

7. Kuchena uye Kuchengeta:

Kurukurai nezvekucheneswa nekugadzirisa zvinodiwa zveporous metal chubhu. Ita shuwa kuti vanogona kucheneswa nyore

uye inoshandiswa zvakare kukwidziridza hupenyu uye kuderedza nguva yekudzikira.

8. Kugadzirisa uye Unyanzvi:

Shanda nemugadziri weOEM ane ruzivo ane rekodhi rekodhi mukugadzira akasarudzika porous simbi machubhu.

Ivo vanofanirwa kuve nehunyanzvi hwekugadzirisa machubhu zvinoenderana nezvinodiwa zvako zvakasiyana.

Nekunyatso funga izvi zvinhu uye nekubatana pamwe nemugadziri weOEM, unogona kuve nechokwadi chekuti

OEM yakakosha porous simbi machubhu akagadzirwa uye akarongedzerwa kuti asangane neyako kusefa system kana yakasarudzika zvinodiwa neprojekiti,

pakupedzisira zvinotungamira mukuvandudza kushanda zvakanaka, kuvimbika, uye kuita.

FAQ

1. Ndezvipi zvakakosha zve porous sintered metal chubhu?

Porous sintered simbi machubhu anopa akati wandei akakosha maficha anoita kuti ave akasiyana uye anobatsira zvakanyanya

zvakasiyana-siyana zvekushandisa. Izvi zvinosanganisira:

*Yakanyanya kusefa Kubudirira:

Iyo chaiyo yekudzora saizi yepore inobvumira kusefa kunoshanda pasi kusvika kune submicron mazinga,

kuve nechokwadi chekubviswa kwezvinosvibisa uye tsvina kubva mumvura nemagasi.

* Durability uye Simba:

Sintering process bonds metal particles, ichipa mechanical simba uye kuramba

ku deformation, kunyange pasi pemamiriro ezvinhu akaoma.

* Yakakura Tembiricha uye Kudzvanya Range:

Iwo machubhu anogona kushanda munzvimbo dzakanyanyisa, achichengetedza kutendeseka kwechimiro uye kusefa

kushanda zvakanaka munzvimbo dzakasiyana siyana dzetembiricha nezvinomanikidza.

*Chemical kuenderana:

Izvo zvine makemikari inert uye inoshingirira mukuora, zvichiita kuti dzive dzakakodzera kusefa zvine hukasha

makemikari uye corrosive media.

* Kucheneswa uye Reusability:

Porous sintered simbi machubhu anogona kucheneswa zviri nyore uye kushandiswazve kakawanda, kuderedza kugadzirisa

mari uye kuwedzera hupenyu hwesefa.

2. Ko machubhu esimbi ane porous sintered anoshanda sei semasefa?

Kushanda kweporous sintered simbi machubhu semasefa kunobva pane yakabatana pore chimiro.

Kana mvura kana gasi richiyerera nemuchubhu, zvinosvibisa uye zvidimbu zvinotorwa mukati me pores

uku uchibvumira svikiro rinodiwa kupfuura. Saizi, kugovera, uye kurongeka kwepores

sarudza kushanda kwefiltration uye rudzi rwezvikamu zvinogona kubviswa. Sintered simbi yakakwirira

porosity uye pores yakanaka inogonesa kusefa kunoshanda, zvichiita kuti machubhu aya ave akanaka kune zvakakosha maapplication uko

kwakanyatso uye kwakavimbika kusefa kunodiwa.

3. Ndedzipi pfungwa dzekuisa porous sintered metal chubhu muhurongwa?

Kuisa kwakaringana kwakakosha kuti uve nechokwadi chekushanda kwakakwana kweporous sintered metal tubes. Zvimwe zvekufungidzira zvinosanganisira:

*Kunyatsoisa chisimbiso:

Ita shuwa yakachengeteka uye isina-inodonhedza yekubatanidza pamativi ese echubhu kudzivirira kunzvenga uye kuchengetedza kusefa kunyatsoita.

*Oriental:

Rongedza chubhu nemazvo kuti ive nechokwadi chekuti inoyerera inoenderana nebasa rayo rakagadzirwa, kungave kuri kusefa, kuburitsa mhepo, kana fluidization.

* Kutsigira uye Dziviriro:

Ipa rubatsiro rwakakwana uye kudzivirira kudzivirira kukanganisa kune machubhu panguva yekuisa uye kushanda.

4. Ndeapi maapplication anogona kushandiswa porous sintered metal chubhu?

Porous sintered simbi machubhu anowana maapplication mumaindasitiri akasiyana siyana, kusanganisira:

Petrochemicals uye kunatsa:Kuti uwane rutsigiro rwecatalyst, kusefa kwezvinwiwa zve process, uye gasi diffusion application.

Pharmaceuticals:Mune sterile venting, gasi kusefa, uye masisitimu ekuunza zvinodhaka.

Kurapa Mvura:Yekuchenesa mvura yetsvina, aeration, uye kusefa kwemvura inonwiwa.

Aerospace:Mumafuta uye hydraulic masisitimu ekusefa uye kufema.

Zvemotokari:Mune emission control, mafuta kusefa, uye lubrication masisitimu.

Zvokudya uye Zvinwiwa:Yechinwiwa carbonation, aeration, uye filtration.

5. Ko porous sintered simbi machubhu anobatsira sei kusimba rehurongwa uye kuita?

Porous sintered simbi machubhu anowedzera mashandiro ehurongwa nekuita ne:

*Kuve nechokwadi chepamusoro kusefa kushanda zvakanaka, zvichitungamira kune yakachena uye yakanyanya kucheneswa zvinwiwa kana magasi.

*Kupa yunifomu yekuyerera kugovera, kudzivirira kutenderera kana kusaenzana kudzvanywa kugovera.

*Kutarisana nemamiriro ezvinhu akaoma, kuderedza nguva yekudzikira uye mari yekugadzirisa.

* Kufambisa gasi kupararira uye fluidization maitiro, optimization kemikari maitiro uye hukuru hwekufambisa mabasa.

6. Ndeapi maitiro ekudzora maitiro anoshandiswa panguva yekugadzirwa kweporous sintered metal chubhu?

HENGKO sePamusoro Sintered Metal Filter vagadziri vanoisa akaomesesa emhando yekudzora matanho mukati mekugadzira maitiro. Izvi zvinosanganisira:

* Hunhu Hwezvinhu: Kushandisa yakakwira-giredhi simbi zvimedu kuti ive nechokwadi chesimba remagetsi uye kuramba kwemakemikari.

* Pore Saizi Kudzora: Kunyatso kudzora kwe sintering paramita kuti uwane inodiwa pore saizi uye kugovera.

* Dimensional Kurongeka: Kuve nechokwadi chekushivirira kwakasimba kusangana nezvinodiwa nevatengi.

* Performance Testing: Kuita kusefa kunyatsoita bvunzo, kudonhedza kudonhedza kuongororwa, uye mekiniki simba ongororo.

Usazeze kutibata nesu kuti tibvunze uyengatikubatsire kukwidziridza yako filtration system kana purojekiti.

Titumire email paka@hengko.comzvino uye tora danho rokutangakune yakawedzerwa kunyatsoshanda uye kuita ne

HENGKO's QualitySintered metal chubhu.