Chii chinonzi Sintering?

Zviri Nyore Kutaura, Sintering inzira yekupisa yekupisa inoshandiswa kushandura zvinhu zvehupfu kuita murwi wakasimba, pasina kusvika pakunyungudika kwakazara.

Shanduko iyi inoitika nekudziisa zvinhu zviri pasi penzvimbo yekunyungudika kusvika zvidimbu zvaro zvanamira kune imwe neimwe.Sintering inoshandiswa zvakanyanya mumaindasitiri akasiyana-siyana akadai sesimbi, ceramics, uye kunyange 3D kudhinda kugadzira zvinhu zvakakora uye zvakasimba kubva muhupfu.

Asi waiziva here kuti pfungwa yokuimba haisati iri kugadzirwa kwemazuva ano?

Muchokwadi, mabviro ayo anogona kurondwa kumashure kusvika ku3000 BC, payaishandiswa kugadzira zvinhu zveceramic.Kunzwisisa kwazvino kwesainzi uye kushandiswa kwakapararira kwemaindasitiri kwe sintering, zvisinei, kwakakura zvakanyanya pamusoro pezana ramakore rapfuura.

Sezvaunogona kufungidzira, sintering inoita basa rakakosha muhuwandu hwekushandisa.Kubva pakugadzira spark plugs, ceramic capacitors, uye korona dzemazino kusvika pakuvaka yepamusoro-tech maindasitiri ezvikamu, sintering yakaratidza kuve yakakosha.

Mhando dzakasiyana dzeSintering

Iye zvino zvaunoziva kuti sintering chii uye kuti yakashandiswa sei munhoroondo yose, inguva yekukuzivisa iwe kumhando dzakasiyana dzekuimba.Hongu, kune inopfuura nzira imwe yekutadza!

Kutanga kumusorois solid-state sintering.Mhando iyi ndiyo inonyanya kukosha uye yakajairika nzira yekuimba.Pano, hupfu hunopisa kusvikira zvimedu zvatanga kubatana.Zvakafanana nemavakirwo aungavaka muzinda wejecha - tsanga dzejecha dzinonamatirana, asi hadzinyungudika.

Tevere,isu tine liquid phase sintering.Rudzi urwu runosanganisira musanganiswa wezvinhu zviviri kana kupfuura.Musanganiswa wacho unopisa kusvika painonyunguduka chimwe chezvigadzirwa zvoita chikamu chemvura, icho chinobatsira mukubatanidza zvidimbu zvakasara zvakasimba pamwechete.

Chetatupane rondedzero inobatidzwa sintering.Muchiitiko ichi, chinowedzera kana chinokonzera chinoshandiswa kukurumidza kufambisa sintering.Funga nezvazvo sekuwedzera mbiriso pahupfu - inoita kuti chingwa chisimuke nekukurumidza.

Pakupedzisira,kune dhizaini-inobatsira sintering matekiniki sekutsikirira kupisa uye spark plasma sintering.Sezvinoratidzwa nezita, matekiniki aya anoshandisa kumanikidzana pamwe nekupisa kukurumidzira sintering uye kugadzira denser zvinhu.

Imwe neimwe mhando ye sintering ine yayo seti yezvakanakira uye inoshandiswa kune chaiwo maapplication.Sarudzo inotsamira pazvinhu zvakadai sechinhu chiri kushandiswa, zvinhu zvinodikanwa zvechigadzirwa chokupedzisira, uye midziyo iripo.Muzvikamu zvinouya, isu tichaongorora zvakadzama mune chaiyo sintered zvinhu uye sintering maitiro pachayo.

Ramba wakagadzirirwa kuti uwane mamwe manzwisisiro anonakidza munyika ye sintering!

Kuongorora Sintered Materials

Zvadaro Tevere tinoda kunzwisisa mhando dzakasiyana dzesintered zvinhu.

Ndine chokwadi parizvino, uri kuwana kurembera kweiyo sintering process.Asi zvakadini nezvigadzirwa zveiyi nzira inofadza?

Chimwe chezvinhu zvinowanzogadzirwa ndeye sintered metal.Maitiro acho anosanganisira kubatanidza uye kugadzira simbi hupfu pasi pekupisa, kuishandura kuita simbi yakasimba.Mhedzisiro isimbi ine chiyero chepamusoro chekuchena uye kufanana.Sintered simbi inogona kuwanikwa mumaindasitiri akasiyana siyana, kubva kumidziyo yemotokari kuenda kumishonga yekurapa, nekuda kwekusimba kwayo uye kuita zvakasiyana.

Tevere,ngatitaure nezvedombo rakasvibiswa.Dombo reSintered rinogadzirwa nekushandisa kupisa uye kumanikidza kumaminerari echisikigo, ivhu, uye feldspar, ichigadzira chinhu chisinga peri.Iwe unowanzo kuwana sintered dombo munzvimbo dzakakwirira-dzinofamba senge kicheni countertops kana mataira ekugezera, uko kusimba kwakakosha.

Sintering inoitawo basa rakakosha mumakeramiki.Maitiro acho anotigonesa kuumba maceramics kuita akawanda ezvimiro zvine ma geometries akaomarara zvisingaite nemaitiro echinyakare.Kubva pamatairi eceramic kusvika kuhari, sintering yakave neshanduko pachikamu ichi.

Pakupedzisira,kune zvimwe zvakasiyana-siyana zvakakosha sintered zvinhu zvekuongorora.Izvi zvinobva kuzvinhu zvakaumbwa, sesimbi-ceramic kombisi, kune inoshanda giredhi zvinhu, uko kuumbwa kunosiyana pane chikamu.

Sintering Process Inotsanangurwa

Ngatifambei kubva kune zvigadzirwa kuenda kune iyo nzira pachayo.Kuimba kunoitika sei, uye ndeapi matanho anokosha anobatanidzwa?

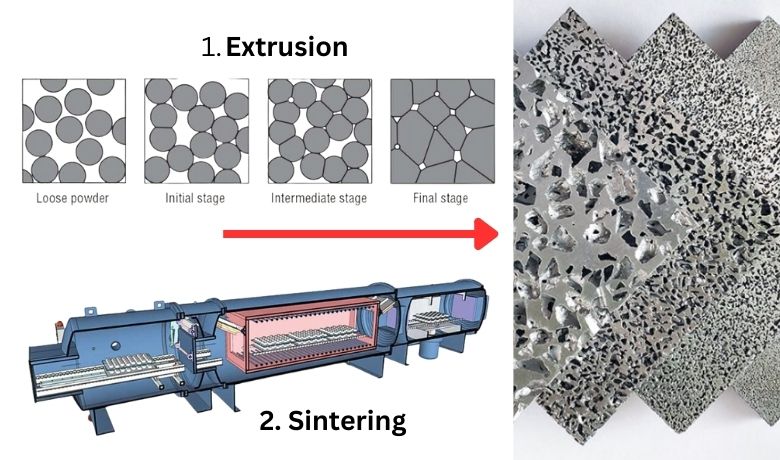

Kutanga, matanho ekutanga-sintering akakosha.Iyo mbishi, ingave simbi, ceramic, kana neimwe nzira, inofanira kugadzirwa muhupfu.Hupfu uhu hunozoumbwa huchidiwa, kazhinji kuburikidza nenzira inonzi 'green compacting'.

Kunotevera kunouya moyo wekuvhiya: iyo sintering process.Hupfu hwakaumbwa hunodziiswa munzvimbo inodzorwa, kazhinji muchoto, kusvika kune tembiricha iri pazasi penzvimbo yayo yekunyungudika.Izvi zvinobvumira zvimedu kuti zvibatane pamwe chete pasina kunyunguduka zvizere, zvichigadzira huremu hwakasimba.

Kana iyo sintering yapera, zvinhu zvinopinda muchikamu chekutonhora.Izvi zvinofanirwa kutariswa nemazvo, sezvo kukurumidza kutonhora kunogona kukonzera kutsemuka kana zvimwe zvimiro zvechimiro.Kutonhodza zvishoma nezvishoma kunoita kuti zvinhu zvigadzike uye zvinyatsosimba.

Pakupedzisira,hatigone kukanganwa zvinhu zvinokanganisa sintering, kunyanya, tembiricha uye nguva.Sintering tembiricha inofanirwa kunge yakakwira zvakakwana kuti ifambise kubatana asi yakadzikira zvakakwana kudzivirira kunyungudika kuzere.Saizvozvo, iyo nguva inopedzwa nezvinhu mukuita sintering inogona kukanganisa zvakanyanya zvimiro zvechigadzirwa chekupedzisira.

Muchikamu chinotevera chesaga yedu yekunyura, isu tinonyura zvakadzika mumasefa akacheneswa uye tigofumura mamiriro anodiwa pakuita sintering.Saka garai makatarisa!

Sintered Filters: An Application Spotlight

Isu takatovhara izvo zvekutanga zvekuimba, takaongorora zvakasiyana-siyana zvesintered, uye takakurukura nezvekuita sintering zvakadzama.

Zvino, ngatitarisei pane akushandiswa kwakananga kwemafirita e sintering.

Zvichida chimwe chezvinyanya kukosha zvekushandisa sintering mukugadzira sintered simbi mafirita.Masefa aya anogadzirwa kubva muhupfu hwesimbi, akaumbwa uye akasiiwa kugadzira porous asi yakasimba sefa yepakati.Saizi yepore yeaya mafirita anogona kunyatsodzorwa, achipa epamusoro kusefa kugona mukuenzanisa neyechinyakare yakarukwa waya mesh mafirita.

Unogona kushamisika,sei kushandisasintered metal filters?Mhinduro iri mukugara kwavo uye kuramba kune tembiricha yepamusoro uye kumanikidza.Izvi zvivakwa zvinoita kuti sintered simbi mafirita ive yakakosha mumaindasitiri kubva kumishonga kusvika kune petrochemicals nekugadzirwa kwechikafu nechinwiwa.

Imwe inonakidza application yekunyura mukusefa ndiyo sintered girazi sefa.Izvi zvinogadzirwa nekubatanidza pamwe tumagirazi tudiki pane tembiricha yepamusoro.Iwo anowanzo shandiswa mumarabhoritari ekusefa uye kugovera gasi nekuda kwekukwira kwazvo kwemakemikari kuramba uye saizi chaiyo yepore.

Sintered mafirita, angave simbi kana girazi, anoratidza kugona kwe sintering mukugadzira zvinhu zvepamusoro zvine zvakanakira zvakasiyana.

Kunzwisisa Sintering Conditions

Zvino, ngatiisei pfungwa dzedu kumamiriro ekupisa.Kana tichitaura nezve muitiro we sintering, mamiriro ayo anoitika pasi pawo anonyanya kukosha.

Chekutanga,tembiricha ye sintering inoita basa rakakosha mukuita.Inoda kunge iri pazasi pekunyungudika kwezvinhu, kubvumira zvimedu kuti zvibatane pasina kunyungudika zvizere.Chiyero chakapfava chinogona kukanganisa zvakanyanya kunaka kwechigadzirwa chekupedzisira.

Zvadaropane nyaya yegesi.Iwe unogona kunge uchishamisika, "Ndeipi gasi rinoshandiswa mukupisa?"Kazhinji, sintering inoitwa mumhepo inodzorwa kudzivirira kuita kusingadiwe pakati pezvinhu uye magasi akapoteredza.Kazhinji, magasi anert senge nitrogen kana argon anoshandiswa, kunyangwe sarudzo chaiyo inotsamira pane izvo zviri kupiswa.

Dzvinyiriro inouyawo mukutamba, kunyanya mukumanikidza-kubatsirwa sintering matekiniki.Kudzvinyirirwa kwepamusoro kunogona kukonzera denser zvinhu, sezvo zvimedu zvinomanikidzwa kuswedera pamwe chete.

Pakupedzisira,zvinhu zvekushandisa uye midziyo inoshandiswa zvinhu zvakakosha.Zvishandiso zvakasiyana zvinobata zvakasiyana pakupisa uye kudzvanywa, zvinoda mamiriro akasiyana ekuti optimal sintering.Rudzi rwechoto kana sintering muchina unogonawo kukanganisa maitiro, sezvatichakurukura muchikamu chinotevera.

Gara wakatarisa apo isu tichiongorora zvakawanda nezve sintering michina uye basa ravo mukuita sintering!

Sintering Equipment: Kutarisa kuSintering Machines

Kusvika ikozvino, tanga tichinyatsoongorora pfungwa yekuimba, sintered zvinhu, uye maitiro acho pachawo.

Iye zvino ngatipenye mwenje pane mutambi mukuru kuseri kwezviitiko:muchina wekuisira.

Muchina we sintering ndiyo ibwe repakona rekuita sintering.Asi chii chaizvo chinonzi sintering machine?Chaizvoizvo, ivira rakasarudzika rakagadzirirwa kuita sintering pasi pemamiriro akanyatso kudzora.

Panemarudzi akasiyana-siyana emichina yekuisairipo, imwe neimwe inokodzera zvinhu zvakasiyana uye nzira dzekuisa.

1. Izvi zvinosanganisiraKuenderera mberi sintering michina(inoshandiswa mumaindasitiri anoda kugadzirwa kwepamusoro-vhoriyamu),

2.Batch sintering michina(zvakawanda zvakajairika mumaLab kana kune yakaderera-vhoriyamu kugadzirwa), uye

3. Vacuum sintering michina(izvo zvinobvumira kunyura mune vacuum kana kudzorwa mhepo).

Mashandiro anoita muchina we sinter ari nyore asi anonakidza.Inopisa zvakafanana zvinhu zvehupfu kune imwe tembiricha, inochengetedza tembiricha iyi kwenguva yakafanotemerwa, uye yobva yatonhodza zvinhu zvishoma nezvishoma, zvese izvi zvichiona kuti mhepo iri mukati inodzorwa.

Kusarudza muchina we sintering chaiwo kwakakosha uye kunoenderana nezvinhu zvakati wandei, kusanganisira izvo zvinofanirwa kucheneswa, iyo inodiwa yekupinda, uye chaiwo sintering mamiriro anodiwa.

Kukosha uye Ramangwana reSintering

Iye zvino yave nguva yekufungisisa pamusoro pemufananidzo mukuru:Chii chinonzi sintering chinoshandiswa,uyenei zvakakosha?

Theapplicationszvekuimba zvakakura uye zvakasiyana-siyana.Inoshandiswa kugadzira zvigadzirwa zvakakora, zvinogara zvine ma geometries akaomarara, kubva kuzvinhu zvemaindasitiri kuenda kuzvinhu zvevatengi.Sintering inotibvumira kugadzira zvigadzirwa zvemhando yepamusoro, senge simbi yakanyungudutswa uye mafirita ane sintered, ane zvimiro zvakasarudzika senge saizi inodzorwa pore uye yakagadziridzwa kusimba.

Asiramangwana rekuimba rinotaridzika sei?Mafambiro ari kubuda anoratidza kuwedzera kwekushandiswa kwekumanikidza-kubatsirwa sintering matekiniki ekugadzira zvinhu zvepamberi.Kuvandudzwa kwemichina yakanyatsoita sintering uye kushandiswa kwe sintering mukuwedzera kugadzira (3D kudhinda) mamwe maitiro anovimbisa.

Zvisinei nekufambira mberi uku, sintering inotarisana nematambudziko, sekuwana kutonga kukuru pamusoro pemaitiro uye kuderedza kushandiswa kwesimba.Kugadzirisa izvi kuchava kiyi yekuvhura mukana wakazara wekuimba mune ramangwana.

Mhedziso:Sintering, nepo iri yakaoma maitiro, inobata yakakosha maindasitiri akasiyana.Kugona kwayo kushandura hupfu hwakapfava kuita hwakasimba, hwakaoma zvinhu hunoita kuti ive hurongwa hunokosha.Sezvo isu tichitarisira kune ramangwana, shanduko uye kunatsiridzwa kwe sintering kunovimbisa mikana inonakidza yezvishandiso zvitsva uye maapplication.

FAQ

1. Chii chinonzi sintering process?

Sintering inzira yekurapa kupisa iyo inoshandura zvinhu zvehupfu kuita murwi wakasimba pasina kunyungudutsa zvinhu zvachose.Inosanganisira kupisa hupfu hwehupfu pasi pekunyunguduka kwayo kusvikira zvimedu zvatanga kunamatira kune mumwe nemumwe, zvichiita misa yakasimba.Maitiro aya anoshandiswa mumaindasitiri akasiyana senge simbi, ceramics, uye yekuwedzera kugadzira kugadzira zvinhu zvakakora uye zvakasimba kubva muhupfu.

2. Kuimba kunoshanda sei?

Kupisa kunosanganisira matanho makuru matatu: kupisa, kubata, uye kutonhora.Iyo yehupfu inotanga kuumbwa uye kuumbwa kuita chimiro chaunoda, yozopisa munzvimbo inodzorwa kusvika kune tembiricha iri pazasi penzvimbo yekunyungudika.Kupisa kunoita kuti zvimedu zvibatane pamwe chete, zvoita hurema hwakasimba.Mushure mekuchengetedza tembiricha iyi kwenguva yakafanotemerwa, zvinhu zvacho zvinobva zvatonhodzwa zvishoma nezvishoma kudzivirira kutsemuka kana zvimwe zvinhu zvechimiro.

3. Ndezvipi zvinhu zvinogona sintered?

Yakasiyana-siyana yemidziyo inogona kusiiwa, kusanganisira simbi, ceramics, mapurasitiki, uye girazi.Zvishandiso zvakasiyana zvinoda mamiriro akasiyana ekupisa, senge tembiricha, kudzvanywa, uye mhepo.Zvimwe zvinhu zvinogona kusiiwa zvakananga, nepo zvimwe zvinoda zvinowedzerwa kana mabhaidha kuti afambise maitiro.

4. Chii chinonzi sintered sefa, uye nei ichishandiswa?

Sintered sefa imhando yesefa inogadzirwa kuburikidza ne sintering process.Inogona kugadzirwa kubva kusimbi, ceramic, kana girazi poda, yakasungirirwa uye inopisa kusvika zvidimbu zvabatana.Saizi yepore yeaya mafirita inogona kunyatsodzorwa, ichipa epamusoro kusefa kugona kana ichienzaniswa neyechinyakare mafirita.Sintered mafirita anogara kwenguva refu uye anoramba tembiricha yakakwira uye kumanikidzwa, zvichiita kuti abatsire mumaindasitiri akasiyana semishonga, petrochemicals, uye kugadzirwa kwechikafu nechinwiwa.

5. Sintering inoshandiswa sei mukuwedzera kugadzira (3D kudhinda)?

Mukuwedzera kugadzira, kana 3D kudhinda, sintering inoshandiswa nenzira dzakadai seselective laser sintering (SLS) uye yakananga simbi laser sintering (DMLS).Idzi nzira dzinosanganisira kushandisa laser kuti sinter upfu zvinhu layer ne layer, kuvaka inodiwa 3D chinhu.Iko kugona kudzora sintering maitiro nenzira kwayo kunoita kuti zvikwanise kuburitsa maumbirwo akaomarara uye geometries zvingave zvakaoma kana zvisingagoneke kuwana nenzira dzechinyakare dzekugadzira.

6. Ndeipi ramangwana rekuimba?

Ramangwana rekuimba rinotaridzika kuva rinovimbisa, nekufambira mberi mune tekinoroji kunovhura mikana mitsva.Semuyenzaniso, kudzvanya-kubatsirwa sintering matekiniki ari kuwedzera kukurumbira pakugadzira zvinhu zvemhando yepamusoro.Kuvandudzwa kwemichina yakanyatsoita uye yakanyatsoita sintering, uye kushandiswa kwe sintering mukuwedzera kugadzira, mamwe maitiro anovimbisa.Zvisinei, matambudziko akadai sekuwana kutonga kukuru pamusoro pekuita uye kuderedza kushandiswa kwesimba kunoda kugadziriswa kuti zvizarure zvizere zvinogona kuita sintering.

Kunyangwe iwe uri kutsvaga kuita sintering maitiro mumabasa ako kana kutsvaga zvemhando yepamusoro sintered zvemapurojekiti ako, HENGKO aripano kuti akubatsire.Chikwata chedu chenyanzvi chakamira chakagadzirira kupa zano, mhinduro, uye masevhisi anoenderana nezvakasarudzika zvaunoda.

Usazengure kutaura nesu kuti uwane rumwe ruzivo nezve maitiro anonakidza ekuimba kana kuongorora zvakasiyana siyana zvezvigadzirwa nemasevhisi.Ingotisiya email paka@hengko.com, uye tichakurumidza kubata.isu takazvipira kukubatsira iwe kushandura mikana yehupfu kuita yakasimba kubudirira!

Tumira meseji yako kwatiri:

Nguva yekutumira: Jul-03-2023